Nissan Juke Service and Repair Manual : Seat belt buckle switch signal circuit (driver side)

Component Function Check

1.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and check the “BUCKLE SW” monitor value.

BUCKLE SW

When driver seat belt is fastened : Off

When driver seat belt is unfastened : On

>> INSPECTION END

Diagnosis Procedure

1.CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (driver side) connector.

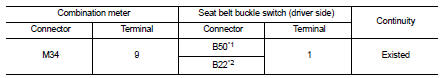

3. Check continuity between combination meter harness connector and seat belt buckle switch (driver side) harness connector.

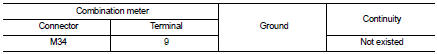

*1: LHD models

*2: RHD models

4. Check harness continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE) GROUND CIRCUIT

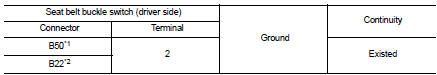

Check harness continuity between seat belt buckle switch (driver side) harness connector and ground.

*1: LHD models

*2: RHD models

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair harness or connector.

Component Inspection

1.CHECK SEAT BELT BUCKLE SWITCH UNIT

1. Turn ignition switch OFF.

2. Disconnect the seat belt buckle switch (driver side) connector.

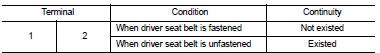

3. Check continuity between terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the seat belt buckle (driver side). Refer to SB-8, "SEAT BELT BUCKLE : Removal and Installation".

Oil pressure switch signal circuit

Oil pressure switch signal circuit

Component Function Check

1.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and check the “OIL W/L” monitor

value.

“OIL W/L”

Ignition switch ON : On

Engine ...

Seat belt buckle switch signal circuit (passenger side)

Seat belt buckle switch signal circuit (passenger side)

Diagnosis Procedure

1.CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (passenger

side) co ...

Other materials:

B209F cranking request circuit

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B209F is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Perform DTC CONFIRMATION PROCEDURE for DTC P1650. Re ...

Bluetooth® Hands-Free Phone System

WARNING

• Use a phone after stopping your vehicle in a safe location. If you have

to use a phone while driving, exercise extreme caution at all times so full attention

may be given to vehicle operation.

• If you find yourself unable to devote full attention to vehicle operation while

talking ...

Vehicle security system cannot BE set

INTELLIGENT KEY

INTELLIGENT KEY : Description

Armed phase is not activated when door is locked using Intelligent Key.

NOTE:

Check that vehicle is under the condition shown in “CONDITIONS OF VEHICLE

(OPERATING CONDITIONS)”

before starting diagnosis, and check each symptom.

CONDITION OF VE ...