Nissan Juke Service and Repair Manual : Removal and Installation Procedure for CVT Unit Connector

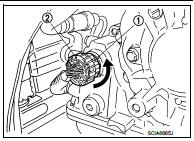

REMOVAL

Rotate bayonet ring (1) counterclockwise, pull out CVT unit harness connector (2) upward and remove it.

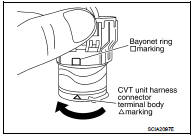

INSTALLATION

1. Align Δ marking on CVT unit harness connector terminal body with marking on bayonet ring, insert CVT unit harness connector, and then rotate bayonet ring clockwise.

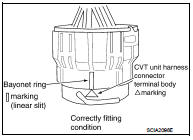

2. Rotate bayonet ring clockwise until Δ marking on CVT unit harness connector terminal body is aligned with the slit on bayonet ring as shown in the figure (correctly fitting condition), install CVT unit harness connector to CVT unit harness connector terminal body.

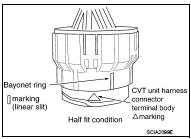

CAUTION:

• Securely align Δ marking on CVT unit harness connector

terminal body with bayonet ring slit. Then, be careful not

to make a half fit condition as shown in the figure.

• Never mistake the slit of bayonet ring for other dent portion.

Precaution for G Sensor Removal/Installation or Replacement

Precaution for G Sensor Removal/Installation or Replacement

CAUTION:

To remove/install or replace G sensor, refer to TM-182, "Description". ...

Precaution

Precaution

NOTE:

If any malfunction occurs in the RE0F10A model transaxle, replace the entire

transaxle assembly.

• Before connecting or disconnecting the TCM harness connector,

turn ignition switch OFF and ...

Other materials:

System

System Diagram

System Description

Supplemental Restraint System (SRS) activates air bag module and seat belt

pre-tensioner when it detects a

frontal collision or a side collision that is more than the specified limit.

Together with other safety devices, it reduces the impact that occupant ...

Seat belt buckle switch signal circuit (passenger side)

Diagnosis Procedure

1.CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (passenger

side) connector.

3. Check continuity between combination meter harness connector and seat belt

buckle swi ...

P1556, P1557 battery temperature sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm ...