Nissan Juke Service and Repair Manual : Brake pedal

Inspection and Adjustment

INSPECTION

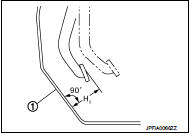

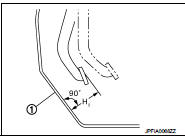

Brake Pedal Height

Check the height (H1) between the dash lower panel (1) and the

brake pedal upper surface.

H1 : Refer to BR-136, "Brake Pedal".

CAUTION:

Remove the floor trim.

Stop Lamp Switch

Check the clearance (C) among the brake pedal lever (1) and the

stop lamp switch (2) threaded end.

C : Refer to BR-136, "Brake Pedal".

CAUTION:

The stop lamp must turn off when the brake pedal is released.

NOTE:

Pull the brake pedal pad to make the clearance between the stop lamp switch threaded end and the brake peal lever.

Brake Switch/Brake Pedal Position Switch Check the clearance (C) among the brake pedal lever (1) and the brake switch/brake pedal position switch (2) threaded end.

C : Refer to BR-136, "Brake Pedal".

NOTE

:

Pull the brake pedal pad to make the clearance between the brake

switch/brake pedal position switch threaded end and the brake peal

lever.

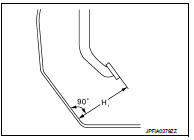

Brake Pedal Play

Press the brake pedal. Check the brake pedal play (A) (stroke until

fluid pressure occurs).

A : Refer to BR-136, "Brake Pedal".

Depressed Brake Pedal Height Check the height between the dash lower panel (1) and the brake pedal upper surface (H2) when depressing the brake pedal at 490 N (50 kg, 110 lb) while turning engine ON.

H2 : Refer to BR-136, "Brake Pedal".

CAUTION:

Remove the floor trim.

ADJUSTMENT

Brake Pedal Height

1. Remove instrument lower panel. Refer to IP-13, "Removal and Installation".

2. Disconnect the stop lamp switch and brake switch/brake pedal position switch harness connector.

3. Loosen the stop lamp switch and brake switch/brake pedal position switch 45° counterclockwise.

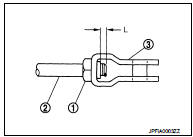

4. Loosen the lock nut (2) of input rod (1).

5. Rotate the input rod, adjust the brake pedal to the specified height (H1).

CAUTION:

The threaded end of the input rod must project to the inner

side (L) of the clevis (3).

H1 : Refer to BR-136, "Brake Pedal".

6. Tighten the lock nut. Refer to BR-111, "Exploded View".

7. Adjust the clearance between the brake pedal lever and the stop lamp switch and brake switch/brake pedal position switch threaded end after adjusting the brake pedal height.

Stop Lamp Switch

1. Remove instrument lower panel. Refer to IP-13, "Removal and Installation".

2. Disconnect the harness connector from stop lamp switch.

3. Loosen the stop lamp switch 45° counterclockwise.

4. Press-fit the stop lamp switch (2) until the stop lamp switch hits the brake pedal lever (1) 45° clockwise while pulling the brake pedal pad slightly.

CAUTION:

• The clearance (C) between the brake pedal lever and stop

lamp switch threaded and must be the specified value.

C : Refer to BR-136, "Brake Pedal".

• The stop lamp must be turned off when the brake pedal is released.

Brake Switch/Brake Pedal Position Switch 1. Remove instrument lower panel. Refer to IP-13, "Removal and Installation".

2. Disconnect the harness connector from brake switch/brake pedal position switch.

3. Loosen the brake switch/brake pedal position switch 45° counterclockwise.

4. Press-fit the brake switch/brake pedal position switch (2) until the brake switch/brake pedal position switch hits the brake pedal lever (1) 45° clockwise while pulling the brake pedal pad slightly.

CAUTION:

The clearance (C) between the brake pedal lever and brake

switch/brake pedal position switch threaded and must be

the specified value.

C : Refer to BR-136, "Brake Pedal".

Depressed Brake Pedal Height 1. Perform the air bleeding. Refer to BR-81, "Bleeding Brake System".

2. Check the height between the dash lower panel (1) and the brake pedal upper surface (H2) when depressing the brake pedal at 490 N (50 kg, 110 lb) while turning engine ON.

H2 : Refer to BR-136, "Brake Pedal".

CAUTION:

Remove the floor trim.

Brake fluid

Brake fluid

Inspection

BRAKE FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified

range (MAX – MIN lines).

• Visually check for any brake fluid leakage around the reservoir

...

Other materials:

Eco information

CAUTION

Do not adjust the display controls while driving so that full attention may

given to vehicle operation.

The following ECO INFO mode will appear on the display by pushing the ECO information

button, then turning the selection dial to scroll through the different screens.

While driving, ...

Removal and Installation

REMOVAL

1. Separate the rear propeller shaft. Refer to DLN-121, "Removal and

Installation".

2. Remove right side drive shaft. Refer to FAX-24, "RIGHT SIDE : Removal and

Installation".

3. Remove catalyst convertor support bracket (RH). EM-35, "4WD : Removal and

Insta ...

B2623 inside antenna

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INSIDE ANT DIAGNOSIS” in “WORK SUPPORT” mode.

3. Perform inside key antenna (“INSIDE ANT DIAGNOSIS”) on “WORK SUPPORT” of

“INTELLIG ...