Nissan Juke Service and Repair Manual : Refilling

1. IInstall reservoir tank if removed, and install radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-17, "Exploded View".

• If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-63, "Setting".

2. Check that each hose clamp has been firmly tightened.

3. Remove air duct (between air cleaner cover assembly and turbocharger inlet tube). Refer to EM-26, "Exploded View".

4. For LHD models, disconnect vacuum hose break booster side, and removal vacuum tube from clamp.

Refer to BR-49, "MR16DDT : Exploded View" (LHD models).

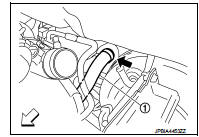

5. Disconnect heater hose (1) at position (

) in the figure.

: Vehicle front

: Vehicle front

• Enhance heater hose as high as possible.

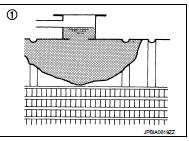

6. Fill radiator (1) to specified level.

CAUTION:

Never adhere the engine coolant to electronic equipments

(alternator etc.).

• Pour coolant slowly of less than 2 (2-1/8 US qt, 1-3/4 Imp qt) a minute to allow air in system to escape.

• When engine coolant overflows disconnected heater hose, connect heater hose, and continue filling the engine coolant.

• Use Genuine NISSAN Engine Coolant or equivalent in its quality mixed with water (distilled or demineralized). Refer to MA-13, "Fluids and Lubricants".

Engine coolant capacity (With reservoir tank at “MAX” level) Refer to CO-29, "Periodical Maintenance Specification".

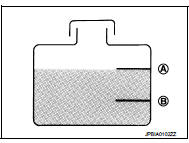

7. Refill reservoir tank to “MAX” level line with engine coolant.

A : MAX

B : MIN

Reservoir tank engine coolant capacity

(At “MAX” level)

Refer to CO-29, "Periodical Maintenance Specification".

8. Install air duct (between air cleaner cover assembly and turbocharger inlet tube). Refer to EM-26, "Exploded View".

9. Install radiator cap.

10. Warm up engine until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000 rpm.

• Check thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine

.

11. Stop the engine and cool down to less than approximately 50°C (122°F).

• Cool down using fan to reduce the time.

• If necessary, refill radiator up to filler neck with engine coolant.

CAUTION:

Never adhere the engine coolant to electronic equipments (alternator etc.)

.

12. Refill reservoir tank to “MAX” level line with engine coolant.

13. Repeat steps 6 through 11 two or more times with radiator cap installed until engine coolant level no longer drops.

14. Check cooling system for leakage with engine running.

15. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

• Sound may be noticeable at heater unit.

16. Repeat step 15 three times.

17. If sound is heard, bleed air from cooling system by repeating step 6 through 11 until reservoir tank level no longer drops.

Draining

Draining

WARNING:

• Never remove radiator cap when engine is hot. Serious burns may occur from

high-pressure engine

coolant escaping from radiator.

• Wrap a thick cloth around the radiator cap. Slowly tur ...

Flushing

Flushing

1. Install radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-17, "Exploded View".

• If water drain plugs on cylin ...

Other materials:

Diagnosis system (BCM) (without intelligent key system)

Description

Air conditioning system performs self-diagnosis, operation check, function

diagnosis, and various settings

using diagnosis function of each control unit.

Common item : consult-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN ...

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosis Description" (without Intelligent Key).

Does it operate normally?

YES >> INSPECTION ...

Door switch

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “BACK DOOR SW”

in

“DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the ...