Nissan Juke Service and Repair Manual : P1588 G sensor

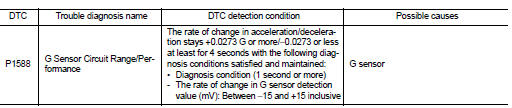

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Start the engine.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “G SPEED”.

4. Drive the vehicle.

5. Maintain the following conditions for 5 seconds or more.

Selector lever : “D” position G SPEED : 0.05 G or more

6. Stop the vehicle.

7. Check the DTC.

Is “P1588” detected? YES >> Go to TM-438, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK G SENSOR SIGNAL

With CONSULT-III

With CONSULT-III

1. Park the vehicle on a level surface.

2. Turn ignition switch ON.

3. Select “Data Monitor” in “TRANSMISSION”.

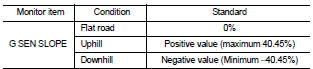

4. Select “G SEN SLOPE”.

5. Swing the vehicle and check if the value varies between −40.45% and 40.45%.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.G SENSOR CALIBRATION (PART 1)

With CONSULT-III

With CONSULT-III

1. Select “Self Diagnostic Results” in “TRANSMISSION”.

2. Touch “Erase”.

>> Perform "G SENSOR CALIBRATION". Refer to TM-377, "Procedure".

3.CHECK G SENSOR

1. Remove the G sensor. TM-492, "Removal and Installation".

2. Connect the all connectors.

3. Turn ignition switch ON.

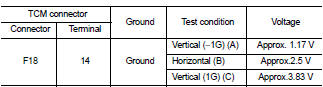

4. Check the voltage between TCM connector terminal and ground.

: Direction of gravitational

: Direction of gravitational

force

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace G sensor.TM-492, "Removal and Installation".

4.G SENSOR CALIBRATION (PART 2)

With CONSULT-III

With CONSULT-III

1. Install G sensor. TM-492, "Removal and Installation".

2. Select “Self Diagnostic Results” in “TRANSMISSION”.

3. Touch “Erase”.

>> Perform "G SENSOR CALIBRATION". Refer to TM-377, "Procedure".

P1586 G sensor

P1586 G sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just befor ...

P1701 TCM

P1701 TCM

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

Other materials:

CSC (concentric slave cylinder)

Exploded View

1. Transaxle assembly

2. CSC (Concentric Slave Cylinder)

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

CAUTION:

• Never reuse CSC (Concentric Slave Cylinder). Because CSC slides back to the

original position

every time when removi ...

P1574 ASCD vehicle speed sensor

Description

The ECM receives two vehicle speed sensor signals via CAN communication line.

One is sent from combination

meter, and the other is from TCM (Transmission control module). The ECM uses

these signals for ASCD

control. Refer to EC-64, "AUTOMATIC SPEED CONTROL DEVICE (ASCD) : Sys ...

Assembly and Installation

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several

different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the

order of tightening is specified,

do ...