Nissan Juke Service and Repair Manual : P1586 G sensor

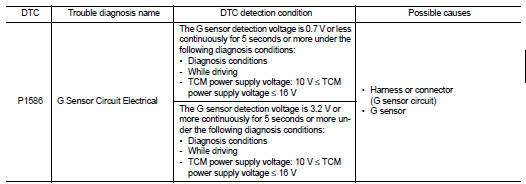

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Start the engine.

2. Drive the vehicle for 10 seconds or more.

3. Stop the vehicle.

4. Check the DTC.

Is “P1586” detected? YES >> Go to TM-435, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

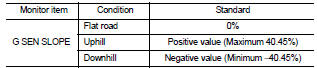

1.CHECK G SENSOR SIGNAL

With CONSULT-III

With CONSULT-III

1. Park the vehicle on a level surface.

2. Turn ignition switch ON.

3. Select “Data Monitor” in “TRANSMISSION”.

4. Select “G SEN SLOPE”.

5. Swing the vehicle and check if the value varies between −40.45% and 40.45%.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.G SENSOR CALIBRATION (PART 1)

With CONSULT-III

With CONSULT-III

1. Select “Self Diagnostic Results” in “TRANSMISSION”.

2. Touch “Erase”.

>> Perform "G SENSOR CALIBRATION". Refer to TM-377, "Procedure".

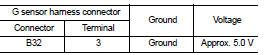

3.CHECK SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect the G sensor connector.

3. Turn ignition switch ON.

4. Check voltage between G sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 8.

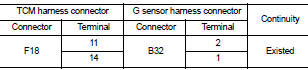

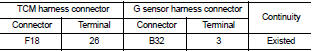

4.CHECK CIRCUIT BETWEEN TCM AND G SENSOR (PART 1)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check continuity between TCM harness connector terminals and G sensor harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CHECK CIRCUIT BETWEEN TCM AND G SENSOR (PART 2)

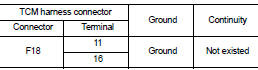

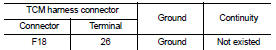

Check the continuity between TCM harness connector terminals and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace the malfunctioning parts.

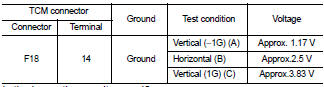

6.CHECK G SENSOR

1. Remove the G sensor. TM-492, "Removal and Installation".

2. Connect the all connectors.

3. Turn ignition switch ON.

4. Check the voltage between TCM connector terminal and ground.

: Direction of gravitational

: Direction of gravitational

force

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace G sensor.TM-492, "Removal and Installation".

7.G SENSOR CALIBRATION (PART 2)

With CONSULT-III

1. Install G sensor. TM-492, "Removal and Installation".

2. Select “Self Diagnostic Results” in “TRANSMISSION”.

3. Touch “Erase”.

>> Perform "G SENSOR CALIBRATION". Refer to TM-377, "Procedure".

8.CHECK SENSOR POWER SUPPLY CIRCUIT (PART 1)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check continuity between TCM harness connector terminal and G sensor harness connector terminal.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace the malfunctioning parts.

9.CHECK SENSOR POWER SUPPLY CIRCUIT (PART 2)

Check the continuity between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace the malfunctioning parts.

P0963 pressure control solenoid A

P0963 pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for a ...

P1588 G sensor

P1588 G sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just befor ...

Other materials:

Configuration (bcm)

Description

Vehicle specification needs to be written with CONSULT-III because it is not

written after replacing BCM.

Configuration has three functions as follows.

NOTE:

Manual setting item: Items which need selection by vehicle specifications

Automatic setting item: Items which are written ...

Front suspension assembly

Inspection

COMPONENT PART

Check the mounting conditions (looseness, backlash) of each component and

component conditions (wear,

damage) are normal.

BALL JOINT AXIAL END PLAY

1. Set front wheels in a straight-ahead position.

2. Measure axial end play by prying it up/down with iron bar or eq ...

Luggage room lamp

Exploded View

1. Bulb housing

2. Bulb

3. Lens

: Pawl

Removal and Installation

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

REMOVAL

1. Insert a remover tool (A) into the gap between luggage room

lamp and luggage side lower finisher RH.

2. Disengage l ...