Nissan Juke Service and Repair Manual : ASCD brake switch

Component Function Check

1.CHECK ASCD BRAKE SWITCH FUNCTION

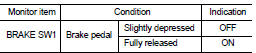

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

3. Select “BRAKE SW1” in “DATA MONITOR” mode.

4. Check “BRAKE SW1” indication under the following conditions.

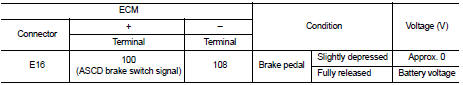

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-765, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK ASCD BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ASCD brake switch harness connector and ground.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• Harness connector E105, M77 (LHD models or RHD models with CVT)

• Harness connector M84, M201 (RHD models with M/T)

• 10A fuse (No. 3)

• Harness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground in harness or connectors.

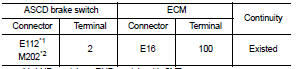

3.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ASCD brake switch harness connector and ECM harness connector.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Harness for open or short between ECM and ASCD brake switch 4.CHECK ASCD BRAKE SWITCH

Refer to EC-766, "Component Inspection (ASCD Brake Switch)" Is the inspection result normal? YES >> GO TO 5.

NO >> Replace ASCD brake switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

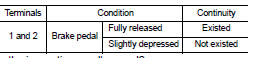

Component Inspection (ASCD Brake Switch)

1.CHECK ASCD BRAKE SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

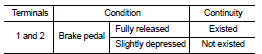

3. Check the continuity between ASCD brake switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ASCD BRAKE SWITCH-II

1. Adjust ASCD brake switch installation. Refer to BR-22, "Inspection and Adjustment" (LHD) or BR-90, "Inspection and Adjustment" (RHD).

2. Check the continuity between ASCD brake switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ASCD brake switch. Refer to BR-88, "Exploded View".

P2A00 A/F sensor 1

P2A00 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor

1 signal is monitored so it will

not shift to LEAN side or RICH side.

DTC CONFIRMATIO ...

ASCD indicator

ASCD indicator

Component Function Check

1.CHECK ASCD INDICATOR FUNCTION

Check ASCD indicator under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-7 ...

Other materials:

Brake assist

When the force applied to the brake pedal exceeds a certain level, the Brake

Assist is activated generating greater braking force than a conventional brake booster

even with light pedal force.

WARNING

The Brake Assist is only an aid to assist braking operation and is not a collision

warning ...

Door switch

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “DOOR SW-BK”

in “DATA

MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the ...

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information. Check that any symptom

occurs other than the interviewed

symptom.

Insufficient cooling/heat ...