Nissan Juke Service and Repair Manual : Push-button ignition switch

Component Function Check

1.CHECK FUNCTION

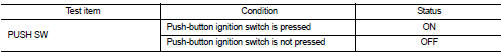

1. Select “PUSH SW” in “Data Monitor” mode with CONSULT-III.

2. Check the push-button ignition switch signal under the following conditions.

Is the indication normal? YES >> INSPECTION END.

NO >> Go to PCS-108, "Diagnosis Procedure".

Diagnosis Procedure

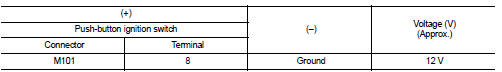

1.CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Disconnect push-button ignition switch connector and IPDM E/R connector.

3. Check voltage between push-button ignition switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

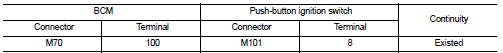

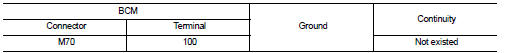

2.CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT 1

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and push-button ignition switch harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK PUSH-BUTTON IGNITION SWITCH OUTPUT SIGNAL 2

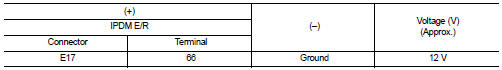

Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT 2

1. Disconnect BCM connector.

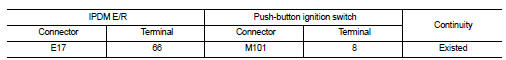

2. Check continuity between IPDM E/R harness connector and push-button ignition switch harness connector.

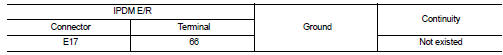

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness.

5.CHECK PUSH-BUTTON IGNITION SWITCH GROUND CIRCUIT

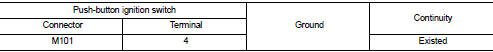

Check continuity between push-button ignition switch harness connector and ground

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK PUSH-BUTTON IGNITION SWITCH

Refer to PCS-109, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace push-button ignition switch.

7.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

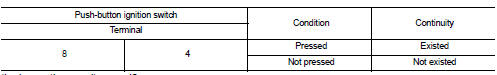

1.CHECK PUSH-BUTTON IGNITION SWITCH

1. Turn ignition switch OFF.

2. Disconnect push-button ignition switch connector.

3. Check continuity between push-button ignition switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace push-button ignition switch.

B26F6 BCM

B26F6 BCM

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B26F6 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B26F6 is disp ...

Push-button ignition switch position indicator

Push-button ignition switch position indicator

Description

Push-button ignition switch changes the power supply position.

BCM maintains the power supply position status.

BCM changes the power supply position with the operation of the push-b ...

Other materials:

Steering switch signal A circuit

Description

Transmits the steering switch signal to NAVI control unit.

Diagnosis Procedure

1.CHECK STEERING SWITCH SIGNAL A CIRCUIT

1. Disconnect NAVI control unit connector and spiral cable connector.

2. Check continuity between NAVI control unit harness connector and spiral cable

harness co ...

B210C starter control relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B210C is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

PCS-30, "DTC Logic".

• When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1

second), the DTC B210C may be

detected.

DTC ...

4WD control module

Removal and Installation

REMOVAL

1. Turn the ignition switch OFF.

2. Remove front (left side) seat. Refer to SE-27, "Removal and Installation".

3. Remove floor carpet. Refer to INT-23, "Removal and Installation".

4. Remove G sensor. Refer to TM-282, "Removal and Install ...