Nissan Juke Service and Repair Manual : Power supply and ground circuit

Diagnosis Procedure

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY

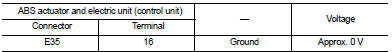

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

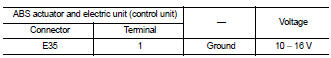

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

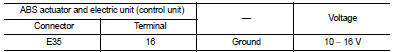

4. Turn the ignition switch ON

CAUTION:

Never start engine

.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 10 A fuse (#57).

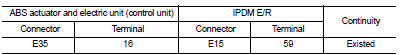

3. Disconnect IPDM E/R harness connector.

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and IPDM E/R harness connector

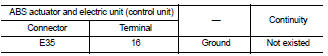

5. Check for continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> Perform trouble diagnosis for ignition power supply. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

3.CHECK MOTOR AND MOTOR RELAY POWER SUPPLY

1. Turn the ignition switch OFF.

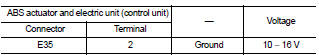

2. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

3. Turn the ignition switch ON.

CAUTION:

Never start engine.

4. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK MOTOR AND MOTOR RELAY POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 30 A fusible link (K).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (1) and 30 A fusible link (K).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

5.CHECK ACTUATOR RELAY, ABS IN VALVE, ABS OUT VALVE POWER SUPPLY

1. Turn the ignition switch OFF.

2. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

3. Turn the ignition switch ON

CAUTION:

Never start engine.

4. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.CHECK ACTUATOR RELAY, ABS IN VALVE, ABS OUT VALVE POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 50 A fusible link (I).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (2) and 50 A fusible link (I).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

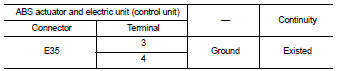

7.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

Check for continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK TERMINAL

• Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

• Check IPDM E/R pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair or replace error-detected parts.

U1010 control unit (can)

U1010 control unit (can)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Parking brake switch

Parking brake switch

Component Function Check

1.CHECK PARKING BRAKE SWITCH OPERATION

Operate the parking brake lever. Then check that the brake warning lamp in

the combination meter turns ON/

OFF correctly.

Is the ...

Other materials:

P0200 fuel injector

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect fuel injector harness connector.

4. Check the continuity between fuel injector harness connector an ...

Ignition position warning function does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM

Check that DTC is not detected with BCM.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refer to BCS-67, "DTC Index".

2.CHECK POWER DOOR LOCK OPERATION

Check power door lock operation.

Does door lock/unlock with d ...

System setting

Temperature Setting Trimmer

DESCRIPTION

If the temperature felt by the customer is different from the air flow

temperature controlled by the temperature

setting, the A/C auto amp. control temperature can be adjusted to compensate for

the temperature setting.

HOW TO SET

With CONSULT-III

P ...