Nissan Juke Service and Repair Manual : Power supply and ground circuit

Diagnosis Procedure

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

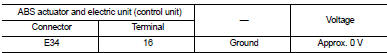

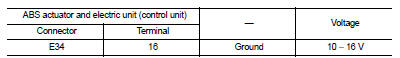

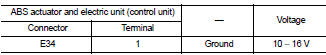

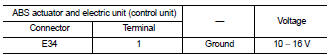

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON

CAUTION:

Never start engine

.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) IGNITION POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 10 A fuse (#57).

3. Disconnect IPDM E/R harness connector.

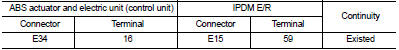

4. Check continuity between ABS actuator and electric unit (control unit) harness connector and IPDM E/R harness connector.

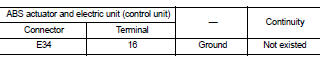

5. Check for continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> Perform trouble diagnosis for ignition power supply. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

3.CHECK MOTOR AND MOTOR RELAY POWER SUPPLY

1. Turn the ignition switch OFF.

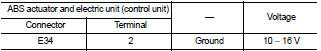

2. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

3. Turn the ignition switch ON.

CAUTION:

Never start engine.

4. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK MOTOR AND MOTOR RELAY POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 30 A fusible link (K).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (1) and 30 A fusible link (K).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

5.CHECK ACTUATOR RELAY, ABS IN VALVE, ABS OUT VALVE POWER SUPPLY

1. Turn the ignition switch OFF.

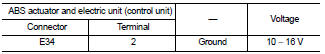

2. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

3. Turn the ignition switch ON

CAUTION:

Never start engine.

4. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.CHECK ACTUATOR RELAY, ABS IN VALVE, ABS OUT VALVE POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 40 A fusible link (F).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (2) and 40 A fusible link (F).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

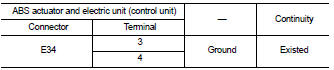

7.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

Check for continuity between ABS actuator and electric unit (control unit) harness connector and the ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK TERMINAL

• Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

• Check IPDM E/R pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair or replace error-detected parts.

U1010 control unit (can)

U1010 control unit (can)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Stop lamp switch

Stop lamp switch

Component Function Check

1.CHECK STOP LAMP SWITCH OPERATION

Depress brake pedal and check that stop lamp turns ON, or release brake pedal

and check stop lamp turns

OFF.

Is the inspection resul ...

Other materials:

Off-road recovery

If the right side or left side wheels leave the road surface, maintain control

of the vehicle by following the procedure below. Please note that this procedure

is only a general guide. The vehicle must be driven as appropriate based on the

conditions of the vehicle, road and traffic.

1. Remai ...

ABS actuator and electric unit (control unit)

Exploded View

LHD

MR16DDT (2WD), HR16DE

1. ABS actuator and electric unit (control

unit)

2. ABS actuator and electric unit (control

unit) harness connector

3. Bracket

A. To front LH caliper

B. To rear RH caliper

C. To rear LH caliper

D. To front RH caliper

E. To master cylinder seco ...

Impossible to shut off engine

Description

CHART 4: IMPOSSIBLE TO SHUT OFF ENGINE

Diagnosis Procedure

1.CHECK ECM POWER SUPPLY AND GROUND CIRCUIT

Check ECM power supply and ground circuit. Refer to EC-885, "Diagnosis

Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or re ...