Nissan Juke Service and Repair Manual : Periodic maintenance

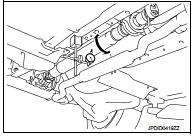

REAR PROPELLER SHAFT

Inspection

APPEARANCE AND NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1. With a dial indicator, measure propeller shaft runout at runout measuring points by rotating final drive companion flange with hands.

Propeller shaft runout : Refer to DLN-125, "Propeller Shaft Runout".

• Propeller shaft runout measuring point (Point “

”)

: Front

: Front

Dimension A: 542 mm (21.34 in) B: 516.5 mm (20.33 in)

2. If runout still exceeds specifications, separate propeller shaft at final drive companion flange or transfer companion flange; then change the phase between companion flange and propeller shaft by the one bolt hole at a time and install propeller shaft.

3. Check runout again. If runout still exceeds specifications, replace propeller shaft assembly.

4. Check the vibration by driving vehicle.

Symptom diagnosis

Symptom diagnosis

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use the chart below to find the cause of the symptom. If necessary, repair or

replace these parts.

×: Applic ...

Removal and installation

Removal and installation

REAR PROPELLER SHAFT ...

Other materials:

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

Units

• The UNITS given in this manual are primarily expressed as the SI UNIT

(International System of Unit), and

alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions

both about range and about th ...

Locking with power door lock switch

Driver’s armrest

Operating the power door lock switch will lock or unlock all the doors. The switch

is located on the driver’s door armrest.

To lock the doors, push the power door lock switch to the lock position 1 with

the driver’s door open, then close the door.

When locking the door this ...