Nissan Juke Service and Repair Manual : P2138 APP sensor

DTC Logic

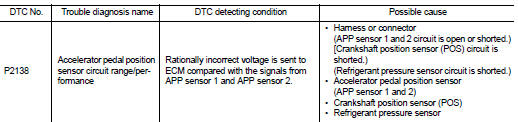

DTC DETECTION LOGIC

NOTE

:

If DTC P2138 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-686, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Go to EC-758, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

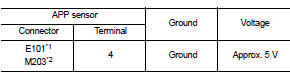

2.CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between APP sensor harness connector and ground.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

3.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-I

Check the voltage between APP sensor harness connector and ground.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 4.

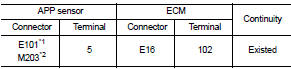

4.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

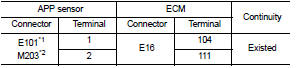

3. Check the continuity between APP sensor harness connector and ECM harness connector.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

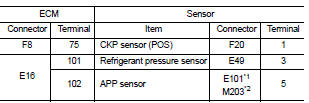

5.CHECK SENSOR POWER SUPPLY CIRCUIT

Check harness for short to power and short to ground, between the following terminals.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair short to ground or short to power in harness or connectors.

6.CHECK COMPONENTS

Check the following.

• Crankshaft position sensor (POS) (Refer to EC-658, "Component Inspection".) • Refrigerant pressure sensor (Refer to EC-790, "Diagnosis Procedure".) Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace malfunctioning component.

7.CHECK APP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

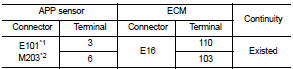

3. Check the continuity between APP sensor harness connector and ECM harness connector as follows.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

8.CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between APP sensor harness connector and ECM harness connector as follows.

*1: LHD models or RHD models with CVT *2: RHD models with M/T

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair open circuit or short to ground or shot to power in harness or connectors.

9.CHECK APP SENSOR

Refer to EC-760, "Component Inspection".

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

Replace accelerator pedal assembly. Refer to ACC-3, "Exploded View".

>> INSPECTION END

11.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

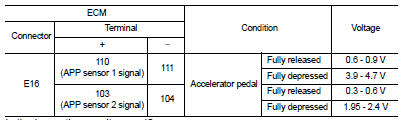

3. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE ACCELERATOR PEDAL ASSEMBLY

Replace accelerator pedal assembly. Refer to ACC-3, "Exploded View".

>> INSPECTION END

P2135 TP sensor

P2135 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2135 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-686, "DTC Logic".

DTC CONFIRMATION PROCE ...

P2A00 A/F sensor 1

P2A00 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor

1 signal is monitored so it will

not shift to LEAN side or RICH side.

DTC CONFIRMATIO ...

Other materials:

Remote keyless entry system

Remote keyless entry function

REMOTE KEYLESS ENTRY FUNCTION : System Diagram

REMOTE KEYLESS ENTRY FUNCTION : System Description

DOOR LOCK AND UNLOCK OPERATION

• When door lock and unlock button of keyfob is pressed, door lock and unlock

signal transmits from keyfob to

BCM via remote keyless ...

Heater and air conditioner

WARNING

• The air conditioner cooling function operates only when the engine

is running.

• Do not leave children or adults who would normally require the support of others

alone in your vehicle. Pets should not be left alone either. On hot, sunny days,

temperatures in a closed vehicle ...

P1642 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector.

3. Check the voltage between thermoplunger control unit harness connector and

ground.

Is the ...