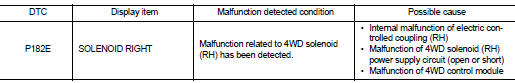

Nissan Juke Service and Repair Manual : P182E 4WD solenoid right

DTC Logic

DTC DETECTION LOGIC

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE (1)

With CONSULT-III

With CONSULT-III

1. Turn the ignition switch OFF to ON, and then wait for 5 seconds or more.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and then wait for 5 seconds or more.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> GO TO 3.

3.DTC REPRODUCTION PROCEDURE (2)

With CONSULT-III

With CONSULT-III

1. Lift up the vehicle.

2. Start the engine, and run at idle for 1 second.

3. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> GO TO 4.

4.DTC REPRODUCTION PROCEDURE (3)

With CONSULT-III

With CONSULT-III

1. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

2. Stop the vehicle.

3. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182E” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-57, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

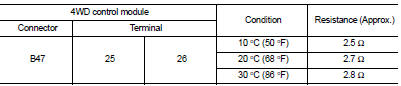

1.CHECK 4WD SOLENOID CIRCUIT (1)

1. Check the resistance between 4WD control module harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

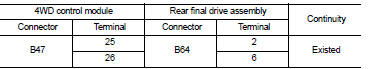

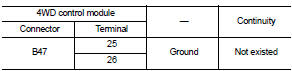

2.CHECK 4WD SOLENOID CIRCUIT (2)

1. Check the continuity between 4WD control module harness connector and rear final drive assembly harness connector.

2. Check the continuity between 4WD control module harness connector and the ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the error-detected parts.

3.CHECK 4WD SOLENOID

Check 4WD solenoid. Refer to DLN-58, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> 4WD solenoid is malfunctioning (RH). Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

4.CHECK TERMINALS AND HARNESS CONNECTORS

1. Check 4WD control module pin terminals for damage or loose connection with harness connector.

2. Check rear final drive assembly pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace the error-detected parts.

Component Inspection

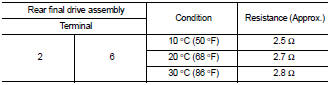

1.CHECK 4WD SOLENOID

1. Turn the ignition switch OFF.

2. Disconnect rear final drive assembly harness connector.

3. Check the resistance between rear final drive assembly connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> 4WD solenoid (RH) is malfunctioning. Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

P182D 4WD solenoid left

P182D 4WD solenoid left

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

P182F coupling temperature sensor left

P182F coupling temperature sensor left

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Back door

Exploded View

REMOVAL

1. Back door weather-strip

2. Back door stay

3. Back door stay lower bracket

4. Bumper rubber

5. Back door striker

6. Back door panel

7. Back door hinge

8. Hole cover

A : Center mark

B : Seam

: Do not reuse

: Body grease

Back door assembly

BACK DOOR ASSEMB ...

Front door lock

Exploded View

1. Door key cylinder assembly (driver

side)

Outside handle escutcheon (passenger

side)

2. Rear gasket

3. Outside handle bracket

4. TORX bolt

5. Key rod (driver side)

6. Door lock assembly

7. Inside handle

8. Outside handle

9. Front gasket

10. Cable clip

: Pawl

: V ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation o ...