Nissan Juke Service and Repair Manual : P182D 4WD solenoid left

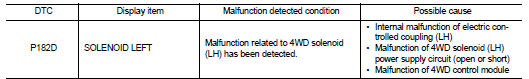

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE (1)

With CONSULT-III

With CONSULT-III

1. Turn the ignition switch OFF to ON, and then wait for 5 seconds or more.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and then wait for 5 seconds or more.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182D” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-54, "Diagnosis Procedure".

NO >> GO TO 3.

3.DTC REPRODUCTION PROCEDURE (2)

With CONSULT-III

With CONSULT-III

1. Lift up the vehicle.

2. Start the engine, and run at idle for 1 second.

3. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182D” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-54, "Diagnosis Procedure".

NO >> GO TO 4.

4.DTC REPRODUCTION PROCEDURE (3)

With CONSULT-III

With CONSULT-III

1. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

2. Stop the vehicle.

3. Drive the vehicle at 30 km/h (19 MPH) or more less for approximately 1 minute.

4. Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is DTC “P182D” detected? YES >> Proceed to diagnosis procedure. Refer to DLN-54, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

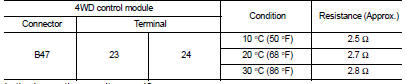

1.CHECK 4WD SOLENOID CIRCUIT (1)

1. Check the resistance between 4WD control module harness connector

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

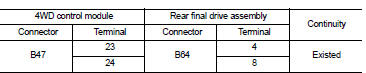

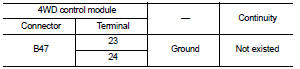

2.CHECK 4WD SOLENOID CIRCUIT (2)

1. Check the continuity between 4WD control module harness connector and rear final drive assembly harness connector.

2. Check the continuity between 4WD control module harness connector and the ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace the error-detected parts.

3.CHECK 4WD SOLENOID

Check 4WD solenoid. Refer to DLN-55, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> 4WD solenoid is malfunctioning (LH). Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

4.CHECK TERMINALS AND HARNESS CONNECTORS

1. Check 4WD control module pin terminals for damage or loose connection with harness connector.

2. Check rear final drive assembly pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace 4WD control module. Refer to DLN-91, "Removal and Installation".

NO >> Repair or replace the error-detected parts.

Component Inspection

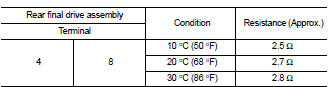

1.CHECK 4WD SOLENOID

1. Turn the ignition switch OFF.

2. Disconnect rear final drive assembly harness connector.

3. Check the resistance between rear final drive assembly connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> 4WD solenoid (LH) is malfunctioning. Replace electric controlled coupling. Refer to DLN-139, "Removal and Installation".

P1829 accelerator pedal position sensor

P1829 accelerator pedal position sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

P182E 4WD solenoid right

P182E 4WD solenoid right

DTC Logic

DTC DETECTION LOGIC

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting th ...

Other materials:

P0638 electric throttle control actuator function

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0638 is displayed with DTC P0120 or P2100, first perform trouble

diagnosis for DTC P0120 or P2100.

Refer to EC-909, "DTC Logic" (P0120), EC-997, "DTC Logic" (P2100).

Diagnosis Procedure

1.CHECK ELECTRIC THROTTLE CONTROL ACTU ...

B26EF steering lock relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B26EF is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B26EF is displayed with DTC U1010, first perform the trouble diagnosis

for DTC U1010. Refer to

BCS-84, "D ...

ECU diagnosis information

EPS control unit

Reference Value

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The output signal indicates the EPS control unit calculation data. The normal

values will be displayed

even in the event that the output circuit (harness) is open.

*1: Almost in accordance with the value of “MOTOR SIG”. ...