Nissan Juke Service and Repair Manual : P0340 CMP sensor (phase)

DTC Logic

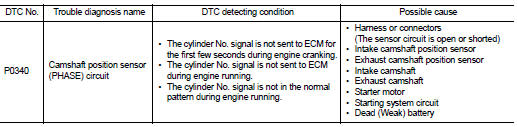

DTC DETECTION LOGIC

NOTE

:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-686, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10.5 V with ignition

switch ON.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-660, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Keep engine speed at more than 800 rpm for at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-660, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK STARTING SYSTEM

Turn ignition switch to START position.

Does the engine turn over? Does the starter motor operate? YES >> GO TO 2.

NO >> Check starting system.

2.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace ground connection.

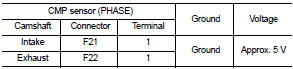

3.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

1. Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

2. Turn ignition switch ON.

3. Check the voltage between CMP sensor (PHASE) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

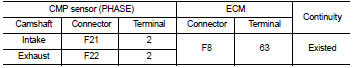

4.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connectors.

3. Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

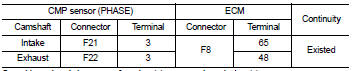

5.CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between CMP sensor (PHASE) harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to EC-662, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace camshaft position sensor (PHASE).

7.CHECK CAMSHAFT (INT)

Check the following.

• Accumulation of debris to the signal plate of camshaft rear end • Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> GO TO 8.

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft.

8.CHECK CAMSHAFT (EXH)

Check the following.

• Accumulation of debris to the signal plate of camshaft rear end • Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> GO TO 9.

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

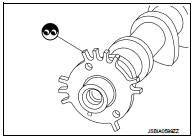

1.CHECK CAMSHAFT POSITION SENSOR (PHASE)-I

1. Turn ignition switch OFF.

2. Loosen the fixing bolt of the sensor.

3. Disconnect camshaft position sensor (PHASE) harness connector.

4. Remove the sensor.

5. Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace camshaft position sensor (PHASE).

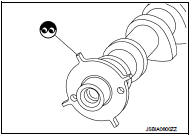

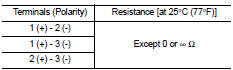

2.CHECK CAMSHAFT POSITION SENSOR (PHASE)-II

Check resistance camshaft position sensor (PHASE) terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace camshaft position sensor (PHASE).

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

P0420 three way catalyst function

P0420 three way catalyst function

DTC Logic

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage ...

Other materials:

P range interlock door lock/unlock function does not operate

Diagnosis Procedure

1.CHECK “AUTOMATIC LOCK/UNLOCK SELECT” SETTING IN “WORK SUPPORT”

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT” mode.

3. Check “AUTOMATIC LOCK/UNLOCK SELECT” in “WORK SUPPORT”.

Refer to DLK-41, "DOOR LOCK : ...

P0087, P0088, P0090 FRP control system

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P0087 or P0090 is displayed with DTC P1197, first perform the trouble

diagnosis for DTC

P1197.

• DTC P0087 or P0090 may be displayed when running out of gas.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been p ...

Intelligent key

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “RKE OPE COUN1” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Intelligent ...