Nissan Juke Service and Repair Manual : P0226 APP sensor

DTC Logic

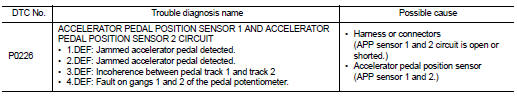

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

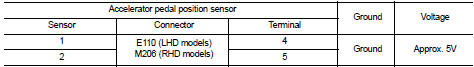

2.CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between accelerator pedal position sensor connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

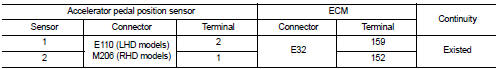

4.CHECK ACCELERATOR PEDAL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

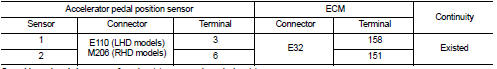

6.CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

8.CHECK ACCELERATOR PEDAL POSITION SENSOR

Refer to EC-929, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace accelerator pedal position sensor.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

Component Inspection

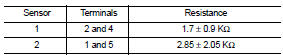

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position sensor harness connector.

3. Check resistance between accelerator pedal position sensor as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace accelerator pedal position sensor

P0225 APP sensor

P0225 APP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P0225 is displayed with DTC P0641, first perform trouble diagnosis for

DTC P0641. Refer to

EC-974, "DTC Logic".

Diagnosis Procedure

1.C ...

P0263, P0266, P0269, P0272 fuel injector

P0263, P0266, P0269, P0272 fuel injector

DTC Logic

DTC DETECTION LOGIC

NOTE:

Check injector code when the above DTC is indicated. If the code is normal,

replace injector showing an applicable

code. If the code is not normal, load inj ...

Other materials:

S mode switch

Component Function Check

1.CHECK S MODE INDICATOR FUNCTION

Check S mode indicator turns ON for approx. 2 seconds when ignition switch

turns ON.

Is the inspection results normal?

YES >> GO TO 2.

NO >> Go to TM-469, "Diagnosis Procedure".

2.CHECK S MODE SWITCH FUNCT ...

Back door opener system

System Diagram

System Descr

BACK DOOR OPENER OPERATION

When back door opener switch is pressed, BCM operates back door opener

actuator.

NOTE:

Back door opener actuator is not for locking the back door. The function is only

to open the back door.

OPERATION CONDITION

If the following ...

P2002 diesel particulate filter

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK DIESEL PARTICULATE FILTER

Refer to EC-995, "Component Inspection".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.REPLACE DIESEL PARTICULATE FILTER

1. Replace diesel particulate filter.

2. Perform ???Dies ...