Nissan Juke Service and Repair Manual : P0225 APP sensor

DTC Logic

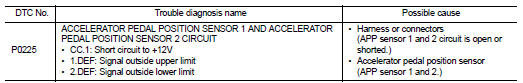

DTC DETECTION LOGIC

NOTE

:

• If DTC P0225 is displayed with DTC P0641, first perform trouble diagnosis for

DTC P0641. Refer to

EC-974, "DTC Logic".

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

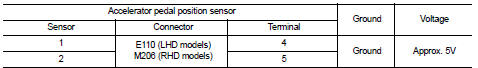

2.CHECK ACCELERATOR PEDAL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between accelerator pedal position sensor connector and ground

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

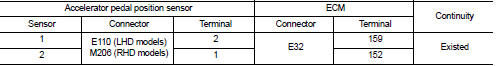

4.CHECK ACCELERATOR PEDAL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

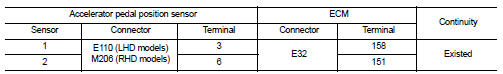

6.CHECK ACCELERATOR PEDAL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between accelerator pedal position sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

• Harness connectors M77, E105 (RHD models) • Harness connectors M95, M202 (RHD models) • Harness for open or short between ECM and accelerator pedal position sensor

>> Repair open circuit or short to ground or short to power in harness or connector.

8.CHECK ACCELERATOR PEDAL POSITION SENSOR

Refer to EC-926, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace accelerator pedal position sensor.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

>> INSPECTION END

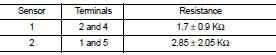

Component Inspection

1.CHECK ACCELERATOR PEDAL POSITION SENSOR

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position sensor harness connector.

3. Check resistance between accelerator pedal position sensor as follows.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace accelerator pedal position sensor.

P0217 engine over temperature

P0217 engine over temperature

DTC Logic

DTC DETECTION LOGIC

If the cooling fan or another component in the cooling system malfunctions,

engine coolant temperature will

rise.

When the engine coolant temperature reaches an a ...

P0226 APP sensor

P0226 APP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

In ...

Other materials:

Wiring diagram

DOOR & LOCK SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Turbocharger (If Equipped)

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean supply

of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

• Always use the recommended oil. Follow ...

Sealant or/and Lubricant

HFC-134a (R-134a) Service Tool and Equipment

• Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with

CFC-12 (R-12) refrigerant and/

or its lubricant.

• Separate and non-interchangeable service equipment must be used for handling

each type of refrigerant/

lubricant.

• R ...