Nissan Juke Service and Repair Manual : Combination switch input circuit

Diagnosis Procedure

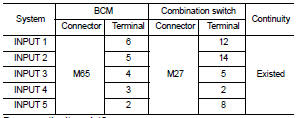

1.CHECK INPUT 1 - 5 CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check continuity between BCM harness connector and combination switch harness connector.

Does continuity exist? YES >> GO TO 2.

NO >> Repair harnesses or connectors.

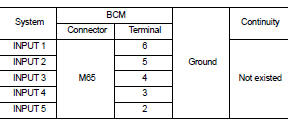

2.CHECK INPUT 1 - 5 CIRCUIT FOR SHORT

Check for continuity between BCM harness connector and ground.

Does continuity exist? YES >> Repair harnesses or connectors.

NO >> GO TO 3.

3.CHECK BCM INPUT SIGNAL

1. Connect BCM and combination switch connectors.

2. Turn ON any switch in the system that is malfunction.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal? Yes >> Replace BCM. Refer to BCS-161, "Removal and Installation".

No >> Replace combination switch.

Combination switch output circuit

Combination switch output circuit

Diagnosis Procedure

1.CHECK OUTPUT 1 - 5 CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check continuity between BCM harness connector and co ...

Symptom diagnosis

Symptom diagnosis

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom Table

1. Perform “Data Monitor” of CONSULT-III to check for any malfunctioning

item.

2. Check the malfunction combinations.

3. Identify the malfuncti ...

Other materials:

Unlock sensor

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “LOCK STATUS” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Unlock sensor is OK. ...

Components

• THE LARGE ILLUSTRATIONS are exploded views (see the following) and

contain tightening torques, lubrication

points, section number of the PARTS CATALOG (e.g. SEC. 440) and other

information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. ...

Vehicle jerks during

Description

The vehicle jerks when ABS function and EBD function operates.

Diagnosis Procedure

1.CHECK SYMPTOM

Check that the vehicle jerks when ABS function and EBD function operates.

Is the inspection result normal?

YES >> Normal

NO >> GO TO 2.

2.PERFORM SELF-DIAGNOSIS

Wit ...