Nissan Juke Service and Repair Manual : P0131 A/F sensor 1

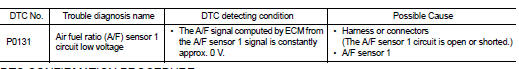

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1 signal is not inordinately low.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10.5 V at idle.

>> GO TO 2.

2.CHECK A/F SENSOR FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Select “ENGINE” using CONSULT-III.

3. Select “A/F SEN1 (B1)” in “DATA MONITOR” mode.

4. Check “A/F SEN1 (B1)” indication.

Is the indication constantly approx. 0 V? YES >> Go to EC-604, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch OFF and wait at least 10 seconds and then restart engine.

2. Drive and accelerate vehicle to more than 40 km/h (25 MPH) within 20 seconds after restarting engine.

CAUTION:

Always drive vehicle at a safe speed.

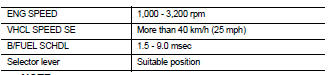

3. Maintain the following conditions for about 20 consecutive seconds.

NOTE

:

• Keep the accelerator pedal as steady as possible during cruising.

• If this procedure is not completed within 1 minute after restarting engine at step 1, return to step 1.

4. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-604, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

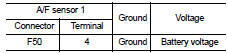

2.CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1

• IPDM E/R harness connector E14

• 20A fuse (No. 43)

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

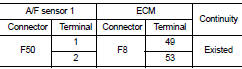

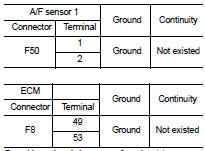

4.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground or ECM harness connector and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

5.CHECK INTERMITTENT INCIDENT

Perform GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace.

6.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner (commercial service tool) and approved anti-seize lubricant (commercial service tool).

>> INSPECTION END

P0130 A/F sensor 1

P0130 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge malfunctions, the diagnosis checks that the A/F signal computed by

ECM from the A/F sensor 1 signal

fluctuates according to fuel feedback control.

DTC CO ...

P0132 A/F sensor 1

P0132 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately high.

DTC CONFIRMATION PROCEDU ...

Other materials:

ECU diagnosis information

ECM

Reference Value

VALUES ON THE DIAGNOSIS TOOL

Remarks:

• Specification data are reference values.

• Specification data are output/input values which are detected or supplied by

the ECM at the connector.

*Specification data may not be directly related to their components

signals/values/o ...

Window washer fluid

To fill the window washer fluid reservoir, lift the cap and pour the window washer

fluid into the reservoir opening.

Add a washer solvent to the washer for better cleaning. In the winter season,

add a windshield washer antifreeze. Follow the manufacturer’s instructions for the

mixture ratio ...

Door lock actuator

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >& ...