Nissan Juke Service and Repair Manual : P0002 fuel pump

DTC Logic

DTC DETECTION LOGIC

NOTE

:

If DTC P0002 is displayed with DTC P0087, P0089, P0090 or P0190, first perform

trouble diagnosis for DTC

P0087, P0089, P0090 or P0190. Refer to EC-895, "DTC Logic" (DTC P0087), EC-897,

"DTC Logic" (DTC

P0089), EC-899, "DTC Logic" (DTC P0090) or EC-917, "DTC Logic" (DTC P0190).

Diagnosis Procedure

1.CHECK LOW PRESSURE FUEL SUPPLY SYSTEM

Refer to EC-867, "Work Procedure (TEST 1: Low Pressure Fuel Supply System Check)".

Is the inspection result normal? OK >> GO TO 2.

NG >> Replace or replace. Then GO TO 9.

2.CHECK INTERNAL FUEL TRANSFER PUMP

Refer to EC-868, "Work Procedure (TEST 2: Internal Fuel Transfer Pump Check)".

Is the inspection result normal? OK >> GO TO 3.

NG >> Replace or replace. Then GO TO 9.

3.CHECK HIGH PRESSURE SUPPLY PUMP (PRESSURE CONTROL VALVE)

Refer to EC-868, "Work Procedure [TEST 3: High Pressure Supply Pump (Pressure Control Valve) Check]".

Is the inspection result normal? OK >> GO TO 4.

NG >> Replace or replace. Then GO TO 9.

4.CHECK HIGH PRESSURE SUPPLY PUMP (VOLUMETRIC CONTROL VALVE)

Refer to EC-869, "Work Procedure [TEST 4: High Pressure Supply Pump (Volumetric Control Valve) Check]".

Is the inspection result normal? OK >> GO TO 5.

NG >> Replace or replace. Then GO TO 9.

5.CHECK RAIL HIGH PRESSURE REGULATION

Refer to EC-871, "Work Procedure (TEST 5: Rail High Pressure Regulation Check)".

Is the inspection result normal? OK >> GO TO 6.

NG >> Replace or replace. Then GO TO 9.

6.CHECK MAJOR LEAK IN FUEL INJECTORS/FUEL INJECTORS OPEN

Refer to EC-876, "Work Procedure (TEST 6: Fuel Injectors Leak Check)".

Is the inspection result normal? OK >> GO TO 7.

NG >> Replace or replace. Then GO TO 9.

7.CHECK INCORRECT FUEL INJECTION QUANTITY

Refer to EC-877, "Work Procedure (TEST 7: Fuel Injection Quantity Check)".

Is the inspection result normal? OK >> GO TO 8.

NG >> Replace or replace. Then GO TO 9.

8.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

Is the inspection result normal? YES >> INSPECTIO END.

NO >> Repair or replace. Then GO TO 9.

9.CLEAR PRESSURE REGULATION

Perform ???PRES REG ADAPTIVE??? in WORK SUPPORT mode with CONSULT-III.

>> INSPECTION END.

Component Inspection

1.CHECK HIGH PRESSURE SUPPLY PUMP (VOLUMETRIC CONTROL VALVE)

1. Turn ignition switch OFF.

2. Disconnect high pressure supply pump (volumetric control valve) harness connector.

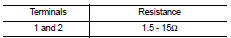

3. Check resistance between high pressure supply pump (volumetric control valve) terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace high pressure supply pump.

P0001 fuel pump

P0001 fuel pump

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0001 is displayed with DTC P0560 or P0657, first perform trouble

diagnosis for DTC P0560 or P0657.

Refer to EC-963, "DTC Logic" (DTC P05 ...

P0016 CKP - CMP correlation

P0016 CKP - CMP correlation

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK CKP SENSOR AND CMP SENSOR

Refer to EC-932, "Diagnosis Procedure" (CKP sensor) and EC-934, "Diagnosis

Procedure" (C ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION ABOUT SYMPTOM

Get detailed information from the customer about the symptom (the condition

and the environment when the

incident/malfunction occurs).

>> GO TO 2.

2.CHECK DTC

1. Check DTC f ...

M&A branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the combination meter for damage, bend

and loose connection

(unit side and connector side).

Is the inspection result n ...

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not fusing.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected

circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CH ...