Nissan Juke Service and Repair Manual : Oil pan (lower)

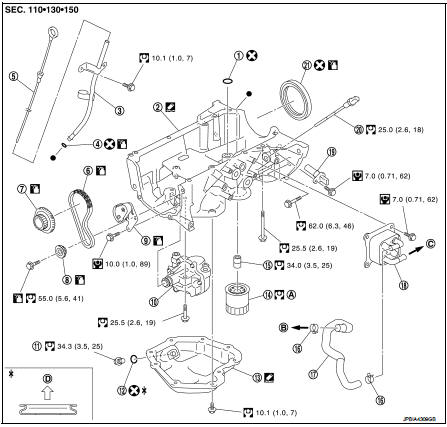

Exploded View

1. O-ring

2. Oil pan (upper)

3. Oil level gauge guide

4. O-ring

5. Oil level gauge

6. Oil pump drive chain

7. Crankshaft sprocket

8. Oil pump sprocket

9. Oil pump chain tensioner

10. Oil pump

11. Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Oil filter

15. Connector bolt

16. Clamp

17. Water hose

18. Oil cooler

19. Crankshaft position sensor

20. Oil level sensor

21. Rear oil seal

A. Refer to LU-11

B. Oil pan side

C. To thermostat housing (M/T models)

To CVT oil warmer (CVT models)

D. Oil pan side

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

: Sealing point

: Sealing point

: Should be lubricated with oil.

: Should be lubricated with oil.

Removal and Installation

1. Drain engine oil. Refer to LU-9, "Draining".

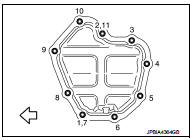

2. Remove oil pan (lower) with the following procedure: a. Loosen mounting bolts in reverse order as shown in the figure.

: Engine front

: Engine front

NOTE:

Disregard the numerical order No.7 and No.11 in removal.

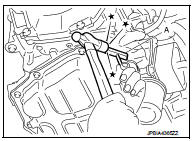

![b. Insert seal cutter [SST: KV10111100 (J-37228)] (A) between oil](images/books/335/2/index.87.jpg)

b. Insert seal cutter [SST: KV10111100 (J-37228)] (A) between oil pan (upper) and oil pan (lower).

CAUTION:

• Be careful not to damage the mating surface.

• Never insert a screwdriver. This damages the mating surfaces.

c. Slide the seal cutter [SST: KV10111100 (J-37228)] by tapping on the side of tool with a hammer.

d. Remove oil pan (lower).

INSTALLATION

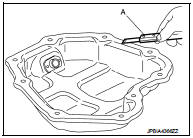

1. Install oil pan (lower) as follows: a. Use a scraper (A) to remove old liquid gasket from mating surfaces.

• Also remove old liquid gasket from mating surface of oil pan (upper).

• Remove old liquid gasket from the bolt holes and threads.

CAUTION:

Never scratch or damage the mating surface when cleaning

off old liquid gasket.

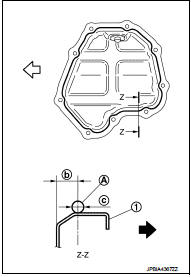

b. Apply a continuous bead of liquid gasket (A) with a tube presser (commercial service tool) as shown in the figure.

1 : Oil pan (lower)

b : 7.5-9.5mm (0.295 - 0.374 in)

c : φ 4.0 - 5.0 mm (0.157 - 0.197 in)

: Engine outside

: Engine outside

Use Genuine Liquid Gasket or equivalent.

CAUTION:

Attaching should be done within 5 minutes after liquid gasket

application.

c. Tighten bolts in numerical order as shown in the figure.

: Engine front

: Engine front

NOTE

:

• Tighten bolts the No.1 and No.2 in two steps.

• The numerical order No.7 and No.11 shows the second steps.

2. Install oil pan drain plug.

• Refer to the figure of components of former page for installation direction of drain plug washer. Refer to EM-99, "Exploded View".

3. Install in the reverse order of removal after this step.

Inspection

INSPECTION AFTER REMOVAL

Clean oil strainer if any object attached.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and adjust engine oil. Refer to LU-8, "Inspection".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level again. Refer to LU-8, "Inspection".

Exhaust manifold

Exhaust manifold

Exploded View

1. Stud bolt

2. Exhaust manifold cover

3. Exhaust manifold

4. Gasket

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every

disassembly.

Remova ...

High pressure fuel pump and fuel hose

High pressure fuel pump and fuel hose

Exploded View

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

1. High pressure fuel pump insulator

2. High pressure fuel pump

3. O-ring

4. Valve lifter ...

Other materials:

Component parts

Component Parts Location

MODELS WITH USB CONNECTION FUNCTION

1. Front door speaker LH

2. Rear door speaker LH

3. Rear door speaker RH

4. Antenna rod

5. Antenna base (antenna amp.)

6. Front door speaker RH

7. Microphone

8. Tweeter LH

9. Steering switch

10. USB connector and AUX jac ...

SPEED LIMITER MAIN SWITCH

Component Function Check

1.CHECK SPEED LIMITER MAIN SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “SL MAIN SW” in “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

3. Check “SL MAIN SW” indication as per the following condition.

Without CONSULT-III

1. Turn ignition ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...