Nissan Juke Service and Repair Manual : Oil filter

Removal and Installation

REMOVAL

1. Remove engine under cover.

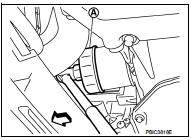

2. Using oil filter wrench [SST: KV10115801] (A), remove oil filter.

: Vehicle front

: Vehicle front

CAUTION:

• Oil filter is provided with relief valve. Use genuine NISSAN

oil filter or equivalent.

• Be careful not to get burned when engine and engine oil may be hot.

• When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

• Completely wipe off any engine oil that adheres to engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil filter.

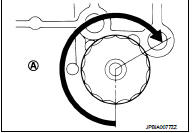

3. Screw oil filter manually until it touches the installation surface, then tighten it by 2/3 turn (A). Or tighten to specification.

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

Inspection

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-25, "Inspection".

2. Start the engine, and check that there is no leakage of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-25, "Inspection".

Engine oil

Engine oil

Inspection

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level.

If engine is already started, stop

it and allow 10 minutes before checking.

...

Other materials:

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and “ABS actuator and electric unit (control

unit)”.

Be sure to erase the malfunction information such as DTC not only for “ABS

actuator ...

Towing recommended by NISSAN

Two-Wheel Drive (2WD) models

NISSAN recommends that your vehicle be towed with the driving (front) wheels

off the ground or place the vehicle on a flat bed truck as illustrated.

CAUTION

• Never tow CVT models with the front wheels on the ground or four wheels

on the ground (forward or ...

Vehicle load capacity

Do not exceed the load limit of your vehicle shown as “The combined weight of

occupants and cargo” on the Tire and Loading Information label. Do not exceed the

number of occupants shown as “Seating Capacity” on the Tire and Loading Information

label.

To get “the combined weight of occupants a ...