Nissan Juke Service and Repair Manual : Line pressure test

Inspection and Judgment

INSPECTION

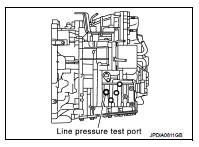

Line Pressure Test Port

Line Pressure Test Procedure 1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the CVT fluid reaches in the range of 50 to 80°C (122 to 176°F), then inspect the amount of CVT fluid and replenish if necessary.

NOTE

:

The CVT fluid temperature rises in the range of 50 to 80°C (122 to 176°F) during

10 minutes of driving.

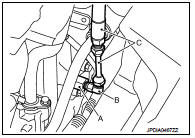

3. After warming up CVT, remove the oil pressure detection plug and install the joint pipe adapter (SST: KV31103600) (A), adapter (SST: 25054000) (B), oil pressure gauge set (commercial service tool) (C).

CAUTION:

When using the oil pressure gauge, be sure to use the Oring

attached to the oil pressure detection plug.

4. Securely engage the parking brake so that the tires do not turn.

5. Start the engine, and then measure the line pressure at both idle and the stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer to TM-186, "Inspection and Judgment".

6. After the measurements are complete, install the oil pressure detection plug and tighten to the specified torque below.

: 7.5 N·m (0.77 kg-m, 66 in-lb)

: 7.5 N·m (0.77 kg-m, 66 in-lb)

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

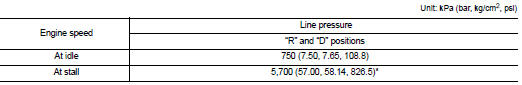

Line Pressure

*: Reference values

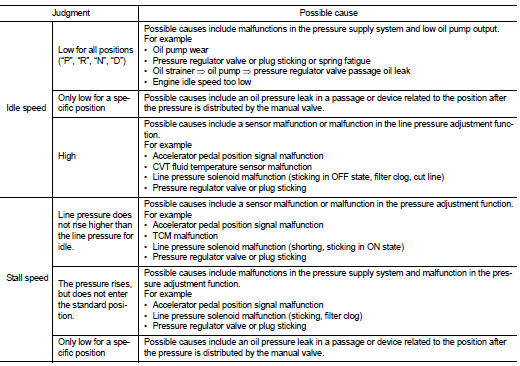

JUDGMENT

Stall test

Stall test

Inspection and Judgment

INSPECTION

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the

CVT fluid temperatur ...

Road test

Road test

Description

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT

and analyze causes of problems.

• The road test consists of the following three parts:

1. “Check Befor ...

Other materials:

Manual Transmission (MT)

WARNING

• Do not downshift abruptly on slippery roads. This may cause a loss

of control.

• Do not over-rev the engine when shifting to a lower gear. This may cause a loss

of control or engine damage.

• When the high fluid temperature protection mode or fail-safe operation occurs,

vehi ...

Audio system symptoms

Models with USB connection function

MODELS WITH USB CONNECTION FUNCTION : Symptom Table

AUDIO SYSTEM

RELATED TO HANDS-FREE PHONE

• Check that the cellular phone is the corresponding type (Bluetooth™

enabled) and Bluetooth™ turns ON.

• Malfunction may occur due to the version change of the p ...

Radiator

Exploded View

1. Cooling fan assembly

2. Mounting rubber (upper)

3. Radiator

4. Mounting rubber (lower)

5. O-ring 6. Drain plug

7. Clamp 8. Radiator hose (lower) (LH)

9. Reservoir tank hose

10. Reservoir tank

11. Reservoir tank cap

12. Clamp

13. Radiator hose (upper)

14. Water ...