Nissan Juke Service and Repair Manual : Stall test

Inspection and Judgment

INSPECTION

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80°C (122 to 176°F). Inspect the amount of CVT fluid. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Install a tachometer where it can be seen by driver during test.

NOTE

:

It is good practice to mark the point of specified engine rpm on

indicator.

5. Start engine, apply foot brake, and place selector lever in “D” position.

6. While holding down the foot brake, gradually press down the accelerator pedal.

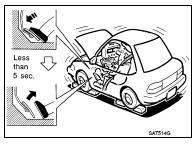

7. Quickly read off the stall speed, and then quickly remove your foot from the accelerator pedal.

CAUTION:

Never hold down the accelerator pedal for more than 5 seconds

during this test.

Stall speed: Refer to TM-308, "Stall Speed".

8. Move the selector lever to the “N” position.

9. Cool down the CVT fluid.

CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “R” position.

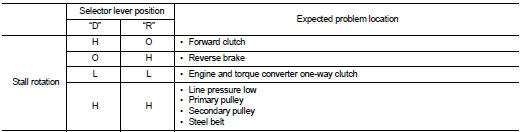

JUDGMENT

O: Stall speed within standard value position.

H: Stall speed is higher than standard value.

L: Stall speed is lower than standard value.

CVT fluid

CVT fluid

Inspection

CHECKING CVT FLUID

The fluid level should be checked with the fluid warmed up to 50 to 80°C (122

to 176°F). The fluid level check

procedure is as follows:

1. Check for fluid leakage.

...

Line pressure test

Line pressure test

Inspection and Judgment

INSPECTION

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to ...

Other materials:

Remote keyless entry system (if so equipped)

It is possible to lock/unlock all doors (including the lift gate), and activate

the panic alarm by using the keyfob from outside the vehicle.

Before locking the doors, make sure the key is not left in the vehicle.

The keyfob can operate at a distance of approximately 33 ft (10 m) from the vehic ...

Component parts

Manual air conditioning system : Component Part Location

1. BCM

• With Intelligent Key: Refer to BCS-

6, "BODY CONTROL SYSTEM :

Component Parts Location".

• Without Intelligent Key: Refer to

BCS-161, "Removal and Installation".

2. Magnet clutch

3. Refrigerant pressure ...

Wiring diagram

Engine control system

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...