Nissan Juke Service and Repair Manual : Inspection

INSPECTION AFTER REMOVAL

Appearance

Check the propeller shaft for bend and damage. If damage is detected, replace

propeller shaft assembly.

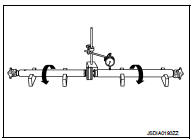

Propeller Shaft Runout

Check propeller shaft runout at measuring points with a dial indicator.

If runout exceeds specifications, replace propeller shaft assembly.

Propeller shaft runout : Refer to DLN-125, "Propeller Shaft Runout".

• Propeller shaft runout measuring point (Point “

”)

: Front

: Front

Dimension A: 542 mm (21.34 in) B: 516.5 mm (20.33 in)

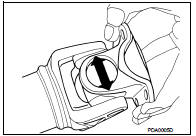

Journal Axial Play

As shown in the figure, while fixing yoke on one side, check axial

play of joint. If it is outside the standard, replace propeller shaft

assembly.

Journal axial play : Refer to DLN-125, "Journal Axial Play".

CAUTION:

Never disassemble joints.

Center Bearing

Check center bearing for noise and damage. If noise or damage is detected,

replace propeller shaft assembly.

CAUTION:

Never disassemble center bearing.

INSPECTION AFTER INSTALLATION

After assembly, perform a driving test to check propeller shaft vibration. If vibration occurred, separate propeller shaft from final drive or transfer. Reinstall companion flange by changing the phase between companion flange and propeller shaft by the one bolt hole at a time. Then perform driving test and check propeller shaft vibration again at each point.

Removal and Installation

Removal and Installation

REMOVAL

1. Shift the transaxle to the neutral position, and then release the parking

brake.

2. Put matching marks on propeller shaft flange yoke and final drive companion

flanges.

CAUTION:

F ...

Other materials:

Door lock and unlock switch

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection resul ...

P0078 EVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...

Refilling

1. Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

Radiator drain plug : Refer to CO-42, "Exploded View".

• If water drain plugs on cylinder block are removed, close and tighten them.

Refer to EM-228, &quo ...