Nissan Juke Service and Repair Manual : Removal and Installation

REMOVAL

1. Shift the transaxle to the neutral position, and then release the parking brake.

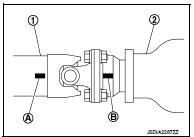

2. Put matching marks on propeller shaft flange yoke and final drive companion flanges.

CAUTION:

For matching marks, use paint. Never damage propeller shaft flange yoke and

final drive companion

flange.

3. Put matching marks on propeller shaft flange yoke and transfer companion flanges.

CAUTION:

For matching marks, use paint. Never damage propeller shaft flange yoke and

transfer companion

flange.

4. Loosen mounting nuts of center bearing mounting bracket.

NOTE

:

Tighten mounting nuts temporarily.

5. Remove propeller shaft assembly fixing bolts and nuts.

6. Remove center bearing mounting bracket fixing nuts.

7. Remove propeller shaft assembly.

CAUTION:

• This procedure requires 2 workers. Constant velocity joint must be handled

with care.

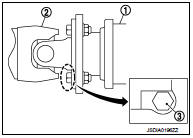

• If constant velocity joint was bent during propeller shaft assembly removal, installation, or transportation, its boot (1) may be damaged. Wrap boot interference area to metal part (2) with shop cloth or rubber to protect boot from breakage.

• Since no retaining pin is included in sliding direction, the boot may be damaged or dropped if the constant velocity joint is slid out 25 mm (0.98 in) or more from the original length. Therefore, handle constant velocity joint by sliding it inward.

8. Perform inspection after removal. Refer to DLN-123, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Align matching marks to install propeller shaft assembly to final drive and transfer companion flanges.

• To install, adjust front and rear position of mount bracket to avoid deflection (front-rear direction of the vehicle) to the center bearing insulator.

• Perform inspection after installation. Refer to DLN-123, "Inspection".

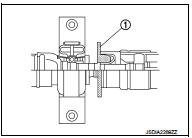

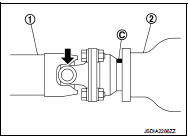

• After tightening the bolts and nuts to the specification torque, check that the bolts (3) on the flange side is tightened as shown in the figure.

1. Final drive assembly 2. Propeller shaft assembly

• If propeller shaft assembly or final drive assembly has been replaced,

connect them as follows:

CAUTION:

Constant velocity joint of a new propeller shaft has a preinstalled

protector (1). Protector must be removed after

installing propeller shaft.

1. Install propeller shaft (1) while aligning its matching mark (A) of propeller shaft with the matching mark (B) of final drive (2) on the joint as close as possible.

2. Temporary tighten bolts and nuts.

3. Press down propeller shaft (1) with matching mark (C) of final drive (2) facing upward. Then tighten fixing bolts and nuts to the specified torque.

Exploded View

Exploded View

1. Propeller shaft assembly

: Vehicle front

: N·m (kg-m, ft-lb)

: Always replace after every

disassem ...

Inspection

Inspection

INSPECTION AFTER REMOVAL

Appearance

Check the propeller shaft for bend and damage. If damage is detected, replace

propeller shaft assembly.

Propeller Shaft Runout

Check propeller shaft runout ...

Other materials:

Diagnosis system (EPS control unit)

Consult-III Function

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes

shown following.

*: The following diagnosis information is erased by erasing.

• DTC

• Freeze frame data (FFD)

ECU IDENTIFICATION

Displays the part number stored in the control unit.

...

Exhaust manifold

Exploded View

1. Exhaust gas temperature sensor 1

2. Gasket

3. Exhaust manifold

4. Exhaust gas pressure sensor 1

A. To cylinder head

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Remove turbocharger assembly. Refer to EM-284, " ...

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES-1 >> With CONSULT-III: GO TO 2.

YES-2 >> Without CONSULT-III: GO TO 3.

NO >> Go to EC-783, "Diagnosis Procedure".

2.IGNITION SIGNAL FUNCTION ...