Nissan Juke Service and Repair Manual : Ignition coil, spark plug and rocker cover

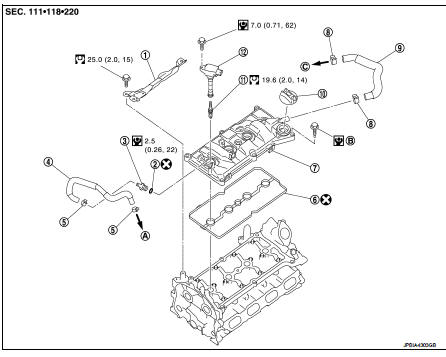

Exploded View

1. Rocker cover protector

2. O-ring

3. PCV control valve

4. PCV hose

5. Clamp

6. Rocker cover gasket

7. Rocker cover

8. Clamp

9. PCV hose

10. Oil filler cap

11. Spark plug

12. Ignition coil

A. To air duct assembly B.Tightening must be done following the installation procedure.

Refer to EM-53

C. To turbocharger inlet tube

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-11, "Draining".

2. Remove engine cover. Refer to EM-25, "Exploded View".

3. Remove intake manifold. Refer to EM-28, "Exploded View".

4. Remove air inlet tube assembly. Refer to EM-31, "Exploded View".

5. Remove PCV hose.

6. Remove rocker cover protector.

7. Disconnect ignition coil harness connector, and them remove ignition coil.

CAUTION:

• Never drop or shock ignition coil.

• Never disassemble ignition coil.

8. Move ignition harness.

9. Remove rocker cover.

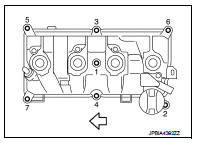

• Loosen bolts in reverse order shown in the figure.

: Engine front

: Engine front

10. Remove PCV valve and PCV hose, if necessary.

11. Remove rocker cover gasket from rocker cover.

INSTALLATION

1. Install the rocker cover gasket to rocker cover.

CAUTION:

Check the gasket is not dropped.

2. Install rocker cover.

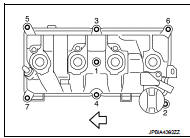

• Tighten bolts in two steps separately in numerical order as shown in the figure.

: Engine front

: Engine front

1st step : 1.96 N·m (0.20 kg-m,

1st step : 1.96 N·m (0.20 kg-m,

17 in-lb)

2nd step : 8.33 N·m (0.85 kg-m, 74

2nd step : 8.33 N·m (0.85 kg-m, 74

in-lb)

3. Install in the reverse order of removal, for the rest of parts.

Fuel injector and fuel tube

Fuel injector and fuel tube

Exploded View

1. Holder

2. Seal ring (white)

3. Backup ring

4. O-ring (blue)

5. Fuel injector

6. Stud bolt

7. Fuel tube assembly

8. Fuel tube insulator

9. Fuel tube protector

10. Fu ...

Unit removal and installation

Unit removal and installation

Engine assembly

2WD

2WD : Exploded View

1. Washer

2. Upper torque rod (RH)

3. Engine mounting insulator (RH)

4. Rear torque rod bracket

5. Rear torque rod

6. Engine mounting insulator (L ...

Other materials:

P183E yaw rate sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks,

damage, loose connections,

chafing and deterioration.

2. Check EVAP canister as follows:

a. Block port (B). Orally blow air through port (A).

Check that air flows freely through port (C).

b. Block port (A ...

C1109 power and ground system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...