Nissan Juke Service and Repair Manual : Glow plug

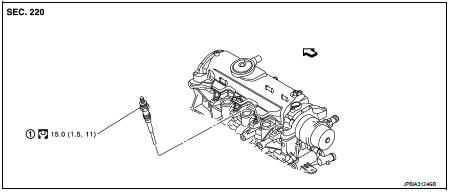

Exploded View

1. Glow plug

Engine front

Engine front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

Remove glow plug only if necessary. If carbon adheres, it may be stuck and

broken.

1. Disconnect the battery cable from the negative terminal.

2. Remove cowl top extension. Refer to EXT-20, "Exploded View".

3. Remove engine under cover.

4. Remove turbocharger air inlet pipe. Refer to EM-280, "Exploded View".

5. Remove air inlet tube assembly and air inlet tube. Refer to EM-281, "Exploded View".

6. Remove High pressure protection cover (upper). Refer to EM-294, "Exploded View".

7. Disconnect harness connector from glow plug.

8. Remove glow plug.

CAUTION:

• When removing or installing, never use such tools as an air impact wrench.

• Handle it carefully without giving any impact, even after removal. [As a guide, if it drops from height of 10 cm (3.94 in) or higher, always replace it.]

INSTALLATION

1. Remove adhered carbon from glow plug installation hole with a reamer.

2. Install glow plug.

3. Install remaining parts in reverse order of removal.

Oil pan

Oil pan

Exploded View

1. Baffle plate

2. Gasket

3. Oil pan

4. O-ring

5. Drain plug

6. Oil level gauge guide

7. Transaxle

8. Crankshaft position sensor (POS)

: N·m (kg-m, ft-lb)

: N·m (kg-m, i ...

Vacuum pump

Vacuum pump

Exploded View

1. Vacuum pump

2. Gasket

3. Damper valve bracket

4. Vacuum hose

A. To electric throttle control actuator

Engine front

: N·m (kg-m, ft-lb)

: Always replace after every

disa ...

Other materials:

B1129 side air bag module RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

4WD warning lamp blinks slowly

Description

4WD warning lamp blinks at approximately 2 seconds intervals while driving.

Diagnosis Procedure

1.CHECK TIRE

Check the following.

• Tire pressure

• Wear condition

• Front and rear tire size (There is no difference between front and rear

tires.)

Is the inspection result normal ...

System (intelligent key system)

Intelligent key system : System Diagram

Intelligent key system : System Description

• The Intelligent Key system is a system that makes it possible to lock and

unlock the door locks (door lock/

unlock function) by carrying the Intelligent Key, which operates based on the

results of electron ...