Nissan Juke Service and Repair Manual : Oil pan

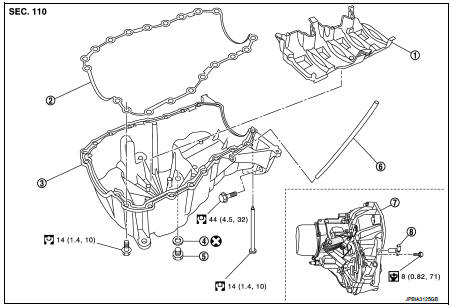

Exploded View

1. Baffle plate

2. Gasket

3. Oil pan

4. O-ring

5. Drain plug

6. Oil level gauge guide

7. Transaxle

8. Crankshaft position sensor (POS)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

CAUTION:

Never drain engine oil when the engine is hot to avoid the danger of being

scalded.

1. Remove engine under cover.

2. Remove RH front wheel. Refer to WT-7, "Exploded View".

3. Remove fender protector RH. Refer to EXT-22, "Exploded View".

4. Remove engine mounting bracket. Refer to EM-326, "Exploded View".

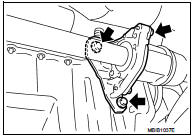

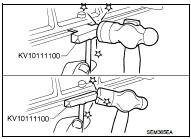

5. Remove center bearing bracket as shown.

6. Remove A/C compressor bracket mounting bolt as shown.

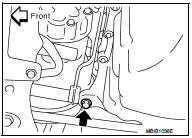

7. Remove oil level gauge guide.

8. Drain engine oil. Refer to LU-34, "Draining".

CAUTION:

Perform when engine is cold.

9. Remove oil pan and transaxle joint bolts.

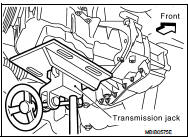

10. Support the engine bottom of the oil pan with a transmission jack etc.

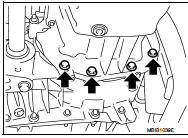

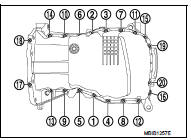

11. Remove oil pan bolt reverse order as shown.

• Insert seal cutter (special service tool) between upper oil pan and cylinder block. Slide tool by tapping on the side of the tool with a hammer.

CAUTION:

Exercise care not to damage mating surface.

12. Remove oil pan and baffle plate.

INSTALLATION

• Install in the reverse order of removal paying attention to the following.

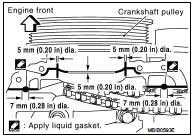

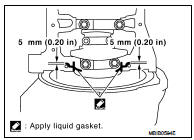

1. Apply liquid gasket as shown.

• Use Genuine Liquid Gasket or equivalent.

2. Install baffle plate.

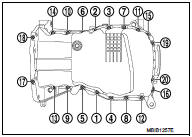

3. Install oil pan.

• Tighten the mounting bolts of oil pan on the clutch housing without locking.

• Tighten the bolts in the numerical order shown in the figure.

: 14 N·m (1.4 kg-m, 10 ft-lb)

: 14 N·m (1.4 kg-m, 10 ft-lb)

• Tighten the mounting bolts of oil pan on the clutch housing.

: 44 N·m (4.5 kg-m, 10 ft-lb)

: 44 N·m (4.5 kg-m, 10 ft-lb)

4. At least 30 minutes after oil pan is installed, pour engine oil.

Inspection

INSPECTION AFTER REMOVAL

Clean oil pump assembly if any object attached.

INSPECTION AFTER INSTALLATION

• Inspection the engine oil level. Refer to LU-33, "Inspection".

• Start the engine, and make sure there is no leak of engine oil. Refer to LU-33, "Inspection".

Exhaust manifold

Exhaust manifold

Exploded View

1. Exhaust gas temperature sensor 1

2. Gasket

3. Exhaust manifold

4. Exhaust gas pressure sensor 1

A. To cylinder head

: N·m (kg-m, ft-lb)

: Always replace after every

disas ...

Glow plug

Glow plug

Exploded View

1. Glow plug

Engine front

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

Remove glow plug only if necessary. If carbon adheres, it may be stuck and

broken.

1. ...

Other materials:

Removal and installation

Exhaust system

Exploded View

2WD

1. Center muffler

2. Mounting rubber

3. Spring

4. Seal bearing

5. Stud bolt

6. Three way catalyst

7. Heated oxygen sensor 2

8. Seal bearing

9. Ring gasket

10. Main muffler

A. To catalyst convertor

: N·m (kg-m, ft-lb)

: Always replace after ever ...

P0031, P0032 A/F sensor 1 heater

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait wait

at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following p ...

Back door opener system

System Diagram

System Description

BACK DOOR OPENER OPERATION

When back door opener switch is pressed, BCM operates back door opener

actuator.

NOTE:

Back door opener actuator is not for locking the back door. The function is only

to open the back door.

OPERATION CONDITION

If the foll ...