Nissan Juke Service and Repair Manual : Front fog lamp aiming adjustment

Description

PREPARATION BEFORE ADJUSTING

NOTE

:

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

• Adjust the tire pressure to the specification.

• Fill with fuel, engine coolant and each oil.

• Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the luggage room.) NOTE

:

Do not remove the temporary tire, jack and on-vehicle tool.

• Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

• Ride alone on the driver seat.

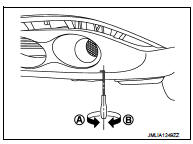

AIMING ADJUSTMENT SCREW

• Turn the aiming adjusting screw for adjustment.

A: DOWN

B: UP

• For the position and direction of the adjusting screw, refer to the figure.

NOTE

:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment Procedure

1. Place the screen.

NOTE

:

• Stop the vehicle facing the wall.

• Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front

fog lamp center and the

screen.

3. Start the engine. Illuminate the front fog lamp.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

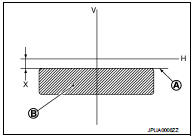

4. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the horizontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

A : Cutoff line

B : High illuminance area

H : Horizontal center line of front fog lamp

V : Vertical center line of front fog lamp

X : Cutoff line height

Headlamp aiming adjustment

Headlamp aiming adjustment

LHD

LHD : Description

PREPARATION BEFORE ADJUSTING

NOTE:

• For details, refer to the regulations in your own country.

• Perform aiming if the vehicle front body has been repaired and/or the headl ...

Other materials:

Service data and specifications (SDS)

Idle Speed

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Ignition Timing

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater f ...

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...

Front oil seal

Exploded View

1. Rear final drive assembly

2. Front oil seal

3. Companion flange

4. Companion flange lock nut

A. Oil seal lip

: Vehicle front

: N·m (kg-m, ft-lb)

: Never reuse parts

: Apply multi purpose grease

: Apply gear oil.

Removal and Installation

REMOVAL

CAUTION:

Verify iden ...