Nissan Juke Service and Repair Manual : Final drive

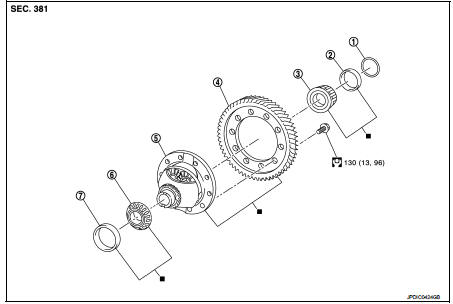

Exploded View

1. Shim

2. Differential side bearing outer race

(transaxle case side)

3. Differential side bearing inner race

(transaxle case side)

4. Final gear

5. Differential case

6. Differential side bearing inner race

(clutch housing side)

7. Differential side bearing outer race

(clutch housing side)

: Replace the parts as a set.

: Replace the parts as a set.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Disassembly

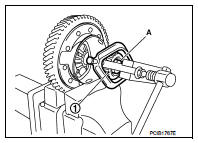

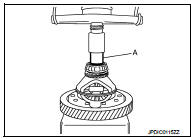

1. Remove differential side bearing inner race (clutch housing side) (1), as per the following procedure.

a. Set a puller [Commercial service tool] to differential side bearing inner race (clutch housing side).

b. Remove differential side bearing inner race (clutch housing side), using the drift (A) [SST: ST33061000].

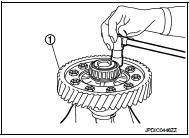

2. Remove final gear mounting bolts, and then remove final gear (1).

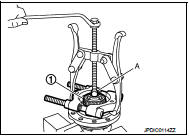

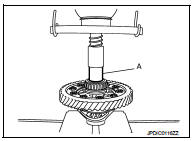

3. Remove differential side bearing inner race (transaxle case side) (1), as per the following procedure.

a. Set a puller [Commercial service tool] to differential side bearing inner race (transaxle case side).

b. Remove differential side bearing inner race (transaxle case side), using a drift (A) [Commercial service tool].

Assembly

1. Install final gear, and then tighten final gear mounting bolts to the specified torque.

CAUTION:

Replace final gear and differential case as a set.

2. Install differential side bearing inner race (clutch housing side), using a drift (A) [Commercial service tool].

CAUTION:

Replace differential side bearing inner race (clutch housing

side) and differential side bearing outer race (clutch housing

side) as a set.

3. Install differential side bearing inner race (transaxle case side), using a drift (A) [Commercial service tool].

CAUTION:

Replace differential side bearing inner race (transaxle case

side) and differential side bearing outer race (transaxle

case side) as a set.

Inspection

INSPECTION AFTER DISASSEMBLY

Gear and Case

Check final gear and differential case. Replace if necessary.

Bearing

Check bearing for damage and unsmooth rotation. Replace if necessary.

Reverse idler shaft and gear

Reverse idler shaft and gear

Exploded View

1. Reverse output gear

2. Snap ring

3. Reverse baulk ring

4. Return spring

5. Needle bearing

6. Seal washer

7. Reverse idler shaft

8. Spacer

9. Reverse input gear

10. L ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specifications

...

Other materials:

Rear wiper motor

Exploded View

1. Rear wiper motor

2. Rear wiper blade

3. Rear wiper arm

4. Rear wiper arm cover

5. Rear wiper pivot seal

A : Model for cold areas

: Pawl

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove rear wiper arm. Refer to WW-84, "Removal a ...

System

CVT control system : System Diagram

CVT control system : System Description

INPUT/OUTPUT SIGNAL TABLE

*: With Nissan Dynamic Control System

SYSTEM DESCRIPTION

• CVT detects the vehicle driving status from switches, sensors and signals,

and controls the vehicle so that

the optimum shift p ...

Power supply and ground circuit

A/C auto AMP. : Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected?

A >>GO TO 2.

B >>GO TO 5.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse (No. 3, located in fuse block (J/B)].

NOTE:

Refer to PG-22, "Fuse, Connector ...