Nissan Juke Service and Repair Manual : Exhaust manifold

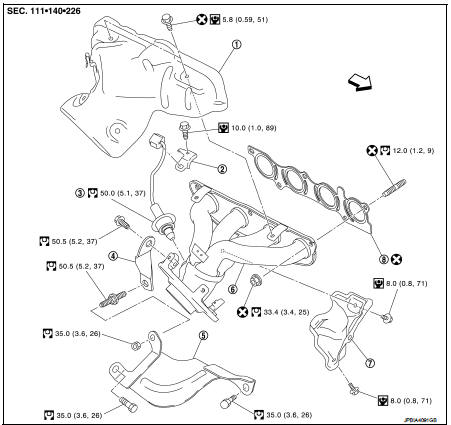

Exploded View

1. Exhaust manifold cover

2. Harness bracket

3. Air fuel ratio sensor 1

4. Exhaust manifold stay

5. Heat insulator

6. Exhaust manifold

7. Exhaust manifold cover

8. Gasket

: Engine front

: Engine front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove exhaust front tube. Refer to EX-12, "Exploded View".

2. Remove air duct. Refer to EM-161, "Exploded View".

3. Remove the harness bracket fixing the harness connector of the air-fuel ratio sensor from the cylinder head on the rear right side.

4. Remove exhaust manifold cover.

5. Remove the air fuel ratio sensor 1.

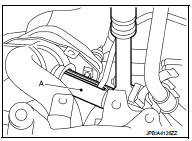

• Using heated oxygen sensor wrench [SST: KV10117100] (A), remove air fuel ratio sensor 1.

CAUTION:

• If O2 sensor is dropped on to a hard surface like a concrete

floor from a height of 0.5 m or more, discard the

sensor and use a new one.

• Clean the mounting area of O2 sensor before installing a new O2 sensor.

NOTE:

The exhaust manifold can be removed and installed without removing the air fuel ratio sensor 1 (Disassembly of harness connector is necessary).

6. Remove exhaust manifold side mounting bolt of exhaust manifold stay.

7. Remove the harness bracket of air fuel ratio sensor 1 from cylinder head.

8. Remove exhaust manifold.

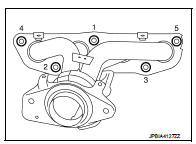

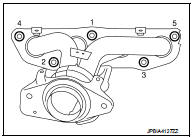

• Loosen nuts in reverse order as shown in the figure.

9. Remove stud bolt from cylinder head.

• Using TORX socket.

10. Remove exhaust manifold cover from exhaust manifold back side.

INSTALLATION

NOte the following, and install in the reverse order of removal.

Exhaust manifold

1. Tighten nuts in numerical order as shown in the figure.

2. Tighten to the specified torque again.

Inspection

INSPECTION AFTER REMOVAL

Surface Distortion

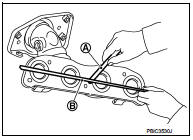

• Using feeler gauge (A) and straightedge (B), check the surface distortion of exhaust manifold mating surface in each exhaust port and entire part.

Limit : Refer to EM-251, "Exhaust Manifold".

• If it exceeds the limit, replace exhaust manifold.

Intake manifold

Intake manifold

Exploded View

1. EVAP canister purge volume control

solenoid valve

2. Hose clamp

3. Vacuum hose

4. Intake manifold support

5. Gasket

6. Intake manifold

7. Electric throttle control actua ...

Oil pan (lower)

Oil pan (lower)

Exploded View

With Oil Cooler

1. Rear oil seal

2. O-ring

3. Oil pan (upper)

4. Oil pump chain tensioner (for oil

pump drive chain)

5. Oil pump drive chain

6. Crankshaft sprocket

7. Oil ...

Other materials:

B26E9 steering status

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Turn ignition switch OFF.

3. Press driver side door switch.

4. Turn ignition switch ON.

5. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

...

Door mirror system (with intelligent key)

LHD

LHD : Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

RHD

RHD : Wiring Diagram

For connector termina ...

High-mounted stop lamp

Exploded View

1. High-mounted stop lamp

2. Seal packing

: N·m (kg-m, in-lb)

Removal and Installation

CAUTION:

Disconnect battery negative terminal or remove the fuse.

REMOVAL

1. Remove blind seal from back door inside.

CAUTION:

Be careful not to damage the blind seal, so that it can b ...