Nissan Juke Service and Repair Manual : Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections, chafing and deterioration.

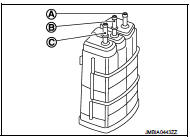

2. Check EVAP canister as follows: a. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

b. Block port (B). Orally blow air through port (A).

Check that air flows freely through port (C).

3. Visually inspect the fuel check valve for cracks, damage, loose connections chafing and deterioration.

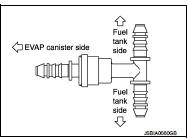

4. Check fuel check valve as follows: a. Blow air through connector on the fuel tank side. A considerable resistance should be felt and a portion of air flow should be directed toward the EVAP canister side.

b. Blow air through connector on EVAP canister side. Air flow should be smoothly directed toward fuel tank side.

c. If fuel check valve is suspected or not properly functioning in step 1 and 2 above, replace it.

5. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

a. Wipe clean valve housing.

b. Check valve opening pressure and vacuum.

Pressure:

15.3 - 20.0 kPa (0.153 - 0.200 bar, 0.156 - 0.204 kg/

cm2, 2.22 - 2.90 psi)

Vacuum:

–6.0 to –3.4 kPa (–0.06 bar to –-0.034bar, –0.061 to –

0.035 kg/cm2, –0.87 to –0.49 psi)

c. If out of specification, replace fuel filler cap as an assembl

Ignition timing

Ignition timing

Inspection

1.CHECK IGNITION TIMING

1. Attach timing light to loop wire as shown.

1. Loop wire

A. Timing light

B. Timing indicator

2. Check ignition timing.

>> INSPECTION END ...

Positive crankcase ventilation

Positive crankcase ventilation

Inspection

1.CHECK PCV VALVE

With engine running at idle, remove PCV valve from rocker cover. A

properly working valve makes a hissing noise as air passes through

it. A strong vacuum should be fel ...

Other materials:

Service Equipment

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation

and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruction ...

U1010 control unit (CAN)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

Diagnosis system (BCM)

Common item : consult-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for ...