Nissan Juke Service and Repair Manual : Drive belt

Checking

• Inspection should be done only when engine is cold or over 30 minutes after the engine is stopped.

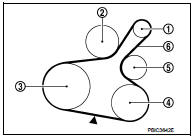

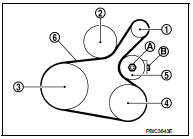

1 : Alternator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor

5 : Idler pulley

6 : Drive belt

• Visually check belts for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley two time clockwise, and check tension on all pulleys is equal before doing the test.

• When measuring deflection, apply 98 N (10 kg, 22 lb) at the (

) marked point.

) marked point.

• Measure the belt tension and frequency with acoustic tension gauge (commercial

service tool) at the ( )

)

marked point.

CAUTION:

• When the tension and frequency are measured, the acoustic tension gauge should

be used.

• When checking immediately after installation, first adjust it to the specified value. Then, after turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflection between pulleys.

Belt Deflection/Belt Tension and Frequency: Refer to EM-250, "Drive Belt".

Tension Adjustment

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New

belt”, because new belt

will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

• When installing a belt, check it is correctly engaged with the pulley groove.

• Never allow oil or engine coolant to get on the belt.

• Never twist or bend the belt strongly.

1. Remove front fender protector (RH). Refer to EXT-22, "Exploded View".

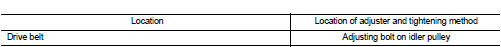

2. After loosening lock nut (A) of idler pulley (5) to release from the specified torque state, temporarily tighten the lock nut to the following torque

4.4 N·m (0.45 kg-m, 39 in-lb)

4.4 N·m (0.45 kg-m, 39 in-lb)

1 : Alternator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor

5 : Idler pulley

6 : Drive belt

CAUTION:

• When the lock nut is loosened excessively, the idler pulley tilts and the

correct tension adjustment

cannot be performed. Never loosen it excessively (more than 45 degrees).

• Put a matching mark on the lock nut (A), and check turning angle with a protractor. Never visually check the tightening angle.

3. Adjust the belt tension by turning the adjusting bolt (B). Refer to EM-154, "Checking".

CAUTION:

• When checking immediately after installation, first adjust it to the specified

value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid

variation in deflection

between pulleys.

• When the tension adjustment is performed, the lock nut should be in the condition at step“ 2”. If the tension adjustment is performed when the lock nut is loosened more than the standard, the idler pulley tilts and the correct tension adjustment cannot be performed.

4. Tighten the lock nut.

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

Removal and Installation

REMOVAL

1. Remove front fender protector (RH). Refer to EXT-22, "Exploded View".

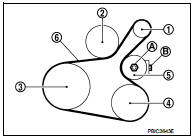

2. Loosen the lock nut (A), and then adjust the belt tension by turning the adjusting bolt (B).

1 : Alternator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor

5 : Idler pulley

6 : Drive belt

3. Remove drive belt.

INSTALLATION

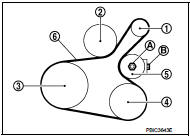

1. Pull the idler pulley in the loosening direction, and then temporarily tighten the lock nut (A) to the following torque.

1 : Alternator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor

5 : Idler pulley

6 : Drive belt

: 4.4 N·m (0.45 kg-m, 39 in-lb)

: 4.4 N·m (0.45 kg-m, 39 in-lb)

NOTE

:

Do not move the lock nut from the tightened position. Go to step “2”.

2. Install the drive belt to each pulley.

CAUTION:

• Check that there is no oil, grease, or coolant, etc. in pulley grooves.

• Check that the belt is securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt (B). Refer to EM-154, "Tension Adjustment".

CAUTION

:

• Perform the belt tension adjustment with the lock nut temporarily tightened

at the step “1” so as

not to tilt the idler pulley.

• When checking immediately after installation, first adjust it to the specified value. Then, after turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflection between pulleys.

4. Tighten the lock nut.

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

5. Check that belt tension of each belt within the standard.

Air cleaner filter

Air cleaner filter

Exploded View

1. Hose clamp

2. PCV hose

3. Hose clamp

4. Air cleaner filter

5. Air cleaner filter case

6. Grommet

7. Inlet Air duct (lower)

8. Grommet

9. Inlet Air duct (upper)

10. B ...

Other materials:

Fuel injector and fuel tube

Exploded View

1. Holder

2. Seal ring (white)

3. Backup ring

4. O-ring (blue)

5. Fuel injector

6. Stud bolt

7. Fuel tube assembly

8. Fuel tube insulator

9. Fuel tube protector

10. Fuel pressure sensor

11. O-ring

12. Fuel tube adaptor

13. Backup ring (white)

14. Backup ring ( ...

P0078 EVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...

Idle air volume learning

Description

Idle Air Volume Learning is a function of ECM to learn the idle air volume

that keeps each engine idle speed

within the specific range. It must be performed under any of the following

conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or i ...