Nissan Juke Service and Repair Manual : Door switch

Component Function Check

1.CHECK FUNCTION

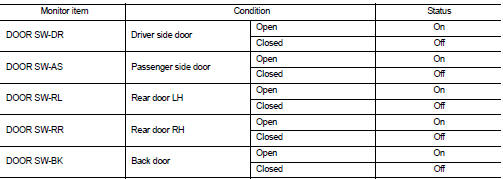

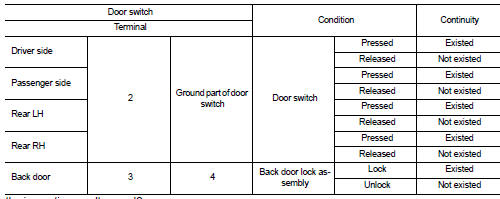

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “BACK DOOR SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door switch is OK.

NO >> Refer to DLK-397, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK DOOR SWITCH INPUT SIGNAL

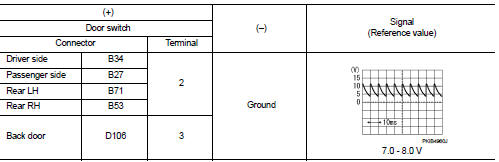

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check signal between malfunctioning door switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES-1 >> Back door: GO TO 3.

YES-2 >> other door: GO TO 4.

NO >> GO TO 2.

2.CHECK DOOR SWITCH CIRCUIT

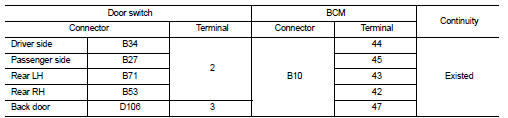

1. Disconnect BCM connector.

2. Check continuity between door switch harness connector and BCM harness connector.

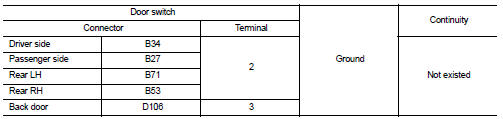

3. Check continuity between door switch harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-161, "Removal and Installation".

NO >> Repair or replace harness.

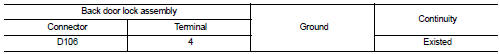

3.CHECK BACK DOOR SWITCH CIRCUIT

Check continuity between back door lock assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR SWITCH

Refer to DLK-398, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace malfunctioning door switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK DOOR SWITCH

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check continuity between door switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunction door switch.

Door lock status indicator

Door lock status indicator

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK IND” in “ACTIVE TEST” mode.

3. Check that the function operates normally according ...

Hazard function

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “MULTI REMOTE ENT” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according ...

Other materials:

Control valve

Exploded View

COMPONENT PARTS LOCATION

1. Transaxle assembly

2. Control valve

3. Bracket

4. O-ring

5. Oil strainer assembly

6. Magnet

7. Drain plug gasket

8. Drain plug

9. Oil pan mounting bolt

10. Oil pan

11. Oil pan gasket

12. Lock nut

13. Washer

14. Manual plate

15. Co ...

Rear window defogger switch

With auto A/C

WITH AUTO A/C : Description

• The rear window defogger is operated by turning the rear window defogger

switch ON.

• The indicator lamp in the rear window defogger switch illuminates when the

rear window defogger is operating.

WITH AUTO A/C : Component Function Check

1.CHECK RE ...

Lubricant

Description

MAINTENANCE OF LUBRICANT LEVEL

The compressor lubricant is circulating in the system together with the

refrigerant. It is necessary to fill compressor

with lubricant when replacing A/C system parts or when a large amount of

refrigerant leakage is

detected. It is important to alwa ...