Nissan Juke Service and Repair Manual : Door lock and unlock switch

Driver side : Component Function Check

1.CHECK FUNCTION

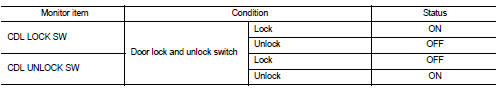

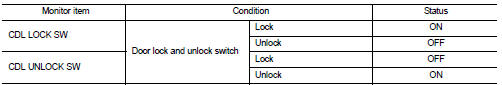

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock and unlock switch is OK.

NO >> Refer to DLK-79, "DRIVER SIDE : Diagnosis Procedure".

Driver side : Diagnosis Procedure

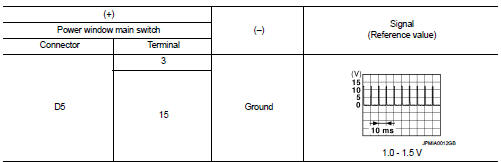

1.CHECK DOOR LOCK AND UNLOCK SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check signal between power window main switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

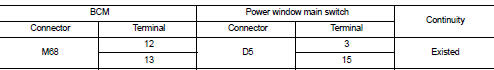

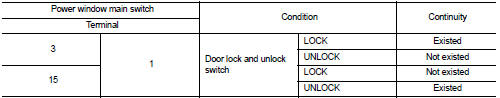

2.CHECK DOOR LOCK AND UNLOCK SWITCH CIRCUIT

1. Disconnect BCM connector and front power window switch (passenger side) connector.

2. Check continuity between BCM harness connector and power window main switch harness connector.

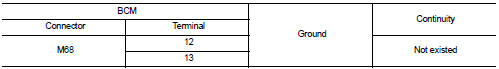

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

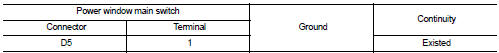

3.CHECK DOOR LOCK AND UNLOCK SWITCH GROUND

Check continuity between power window main switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR LOCK AND UNLOCK SWITCH

Refer to DLK-80, "DRIVER SIDE : Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace power window main switch. Refer to PWC-44, "Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Driver side : Component Inspection

1.CHECK DOOR LOCK AND UNLOCK SWITCH

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between power window main switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace power window main switch.

Passenger side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock and unlock switch is OK.

NO >> Refer to DLK-81, "PASSENGER SIDE : Diagnosis Procedure".

Passenger side : Diagnosis Procedure

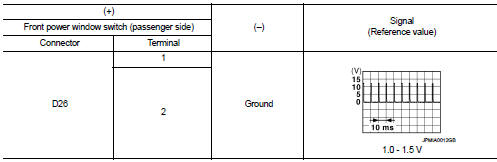

1.CHECK DOOR LOCK AND UNLOCK SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Check signal between front power window switch (passenger side) harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

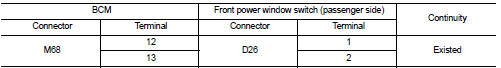

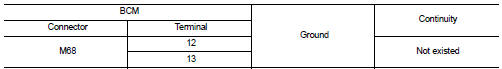

2.CHECK DOOR LOCK AND UNLOCK SWITCH CIRCUIT

1. Disconnect BCM connector and power window main switch connector.

2. Check continuity between BCM harness connector and front power window switch (passenger side) harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

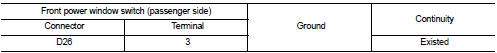

3.CHECK DOOR LOCK AND UNLOCK SWITCH GROUND

Check continuity between front power window switch (passenger side) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR LOCK AND UNLOCK SWITCH

Refer to DLK-82, "PASSENGER SIDE : Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace front power window switch (passenger side). Refer to PWC-44, "Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

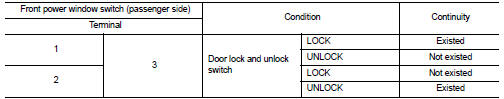

Passenger side : Component Inspection

1.CHECK DOOR LOCK AND UNLOCK SWITCH

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Check continuity between front power window switch (passenger side) terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace front power window switch (passenger side).

Door lock actuator

Door lock actuator

Driver side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally ...

Door lock status indicator

Door lock status indicator

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK IND” in “ACTIVE TEST” mode.

3. Check that the function operates normally according ...

Other materials:

Electric foldable door mirror does not operate

Diagnosis Procedure

1.CHECK DOOR MIRROR (OPEN/CLOSE MOTOR) CIRCUIT

Check door mirror (open/close motor) circuit.

Refer to MIR-25, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONF ...

P0717 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...

Evaporative emission system

Inspection

1. Visually inspect EVAP vapor lines for improper attachment and for cracks,

damage, loose connections,

chafing and deterioration.

2. Check EVAP canister as follows:

a. Block port (A). Orally blow air through port (B).

Check that air flows freely through port (C).

b. Block port (B ...