Nissan Juke Service and Repair Manual : Door lock actuator

Driver side

DRIVER SIDE : Component Function Check

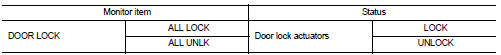

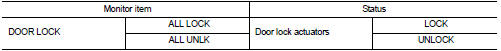

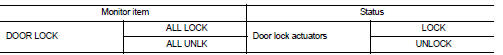

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock actuator is OK.

NO >> Refer to DLK-386, "DRIVER SIDE : Diagnosis Procedure".

DRIVER SIDE : Diagnosis Procedure

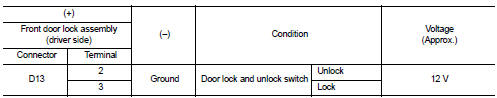

1.CHECK DOOR LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check voltage between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (driver side).

NO >> GO TO 2.

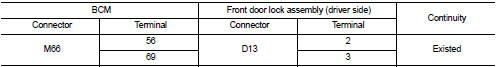

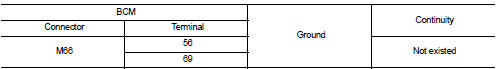

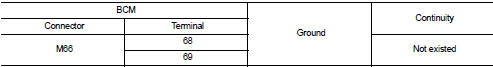

2.CHECK DOOR LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connector

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

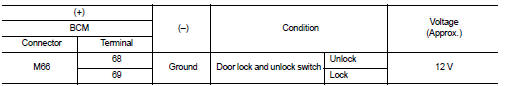

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

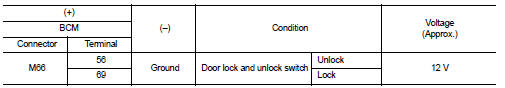

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each door lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Passenger side

PASSENGER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock actuator is OK.

NO >> Refer to DLK-386, "DRIVER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis Procedure

1.CHECK DOOR LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (passenger side) connector.

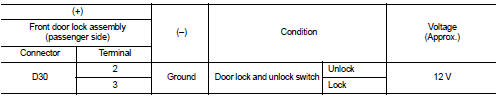

3. Check voltage between front door lock assembly (passenger side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (passenger side).

NO >> GO TO 2.

2.CHECK DOOR LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

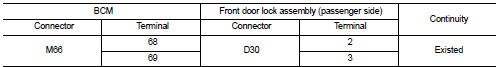

2. Check continuity between BCM harness connector and front door lock assembly (passenger side) harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each door lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Rear LH

REAR LH : Component Function Check

1.CHECK FUNCTION

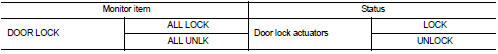

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock actuator is OK.

NO >> Refer to DLK-386, "DRIVER SIDE : Diagnosis Procedure".

REAR LH : Diagnosis Procedure

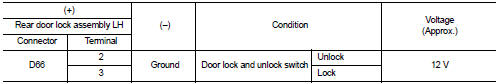

1.CHECK DOOR LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly LH connector.

3. Check voltage between rear door lock assembly LH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly LH.

NO >> GO TO 2.

2.CHECK DOOR LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

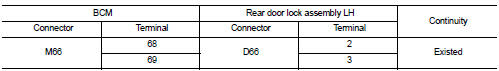

2. Check continuity between BCM harness connector and rear door lock assembly LH harness connecto

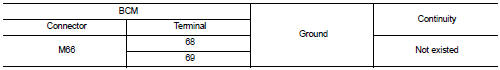

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

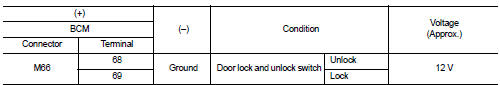

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each door lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Rear RH

REAR RH : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door lock actuator is OK.

NO >> Refer to DLK-386, "DRIVER SIDE : Diagnosis Procedure".

REAR RH : Diagnosis Procedure

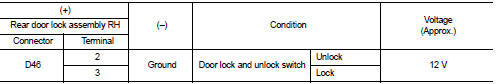

1.CHECK DOOR LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly RH connector.

3. Check voltage between rear door lock assembly RH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly RH.

NO >> GO TO 2.

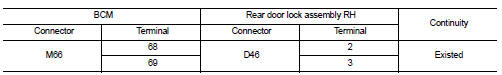

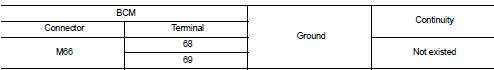

2.CHECK DOOR LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and rear door lock assembly RH harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

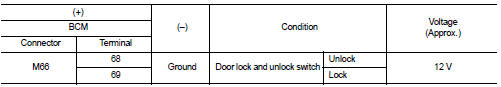

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each door lock actuator.

NO >> Replace BCM. Refer to BCS-161, "Removal and Installation".

Back door opener switch

Back door opener switch

Component Function Check

1.CHECK FUNCTION

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TRNK OPNR SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to t ...

Door lock and unlock switch

Door lock and unlock switch

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check tha ...

Other materials:

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected

circuit if a fuse or fusible link is

blown.

NO >> GO TO 2. ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

applications. It is an on-board multiplex

communication line with high data communication speed and excellent error

detection ability. A modern

vehicle is equipped with many ECMs, and each control unit shar ...

Wiring diagram

CAN SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...