Nissan Juke Service and Repair Manual : Cooler pipe and hose

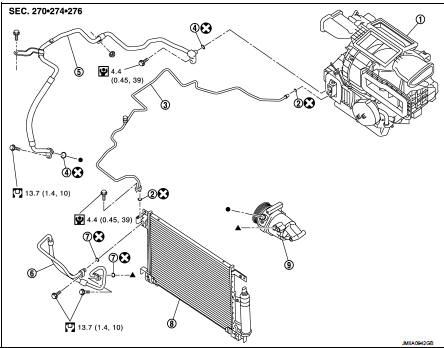

Exploded View

1. A/C unit assembly

2. O-ring

3. High-pressure pipe

4. O-ring

5. Low-pressure flexible hose

6. High-pressure flexible hose

7. O-ring

8. Condenser

9. Compressor

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

High-pressure flexible hose : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Remove front bumper fascia assembly. Refer to EXT-13, "Removal and Installation".

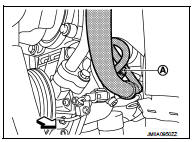

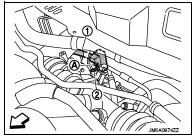

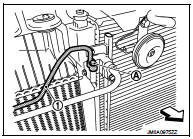

3. Remove mounting bolt (A), and then disconnect high-pressure flexible hose from condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with

suitable material such as vinyl tape to avoid the entry of air.

: Vehicle front

: Vehicle front

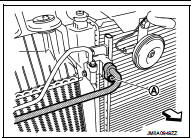

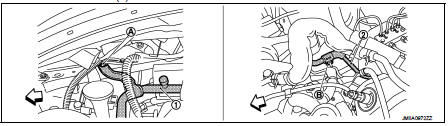

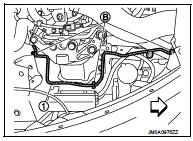

4. Remove mounting bolt (A), and then disconnect high-pressure flexible hose from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

: Vehicle front

: Vehicle front

5. Remove high-pressure flexible hose from vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

Low-pressure flexible hose : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Remove front bumper fascia asembly. Refer to EXT-13, "Removal and Installation".

3. Remove cowl top extension. Refer to EXT-20, "Removal and Installation".

4. Remove mounting nut, and then move lower dash insulator aside.

: Nut

: Nut

: Vehicle front

: Vehicle front

5. Remove mounting bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from expansion valve. Refer to HA-116, "EXPANSION VALVE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

: Vehicle front

: Vehicle front

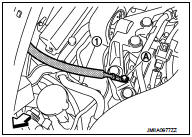

6. Remove mounting bolt (A) of low-pressure flexible hose front side (1) and mounting nut (B) of low-pressure flexible hose rear side (2).

: Vehicle front

: Vehicle front

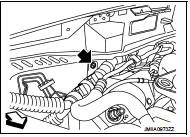

7. Remove ground wire mounting bolt (A), and then move ground wire (1) aside.

: Vehicle front

: Vehicle front

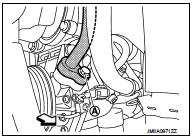

8. Remove mounting bolt (A), and then disconnect low-pressure flexible hose from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

: Vehicle front

: Vehicle front

9. Remove low-pressure flexible hose from vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

High-pressure pipe : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Remove low-pressure flexible hose. Refer to HA-91, "LOW-PRESSURE FLEXIBLE HOSE : Removal and Installation".

3. Remove mounting bolt (A), and then disconnect high-pressure pipe (1) from condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with

suitable material such as vinyl tape to avoid the entry of air.

: Vehicle front

: Vehicle front

4. Remove high-pressure pipe (1) fixing clips (B), and then remove high-pressure pipe from vehicle.

: Vehicle front

: Vehicle front

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

Compressor

Compressor

Exploded View

REMOVAL

1. High-pressure flexible hose

2. O-ring

3. Compressor

4. O-ring

5. Low-pressure flexible hose

A. To condenser

B. To evaporator

: N·m (kg-m, ft-lb)

DISASSEMBLY

...

Condenser

Condenser

Exploded View

1. Condenser

2. Condenser lower bracket RH

3. Condenser lower bracket LH

4. O-ring

5. Liquid tank braket

6. Liquid tank

7. Braket

8. O-ring

9. Refrigerant pressure senso ...

Other materials:

Fluid cooler system

Exploded View

1. Copper washer

2. CVT fluid cooler tube

3. Hose clamp

4. Fluid cooler hose A

5. Fluid cooler tube

6. Fluid cooler hose B

7. Fluid cooler hose C

8. Transaxle assembly

9. Fluid cooler hose D

10. Fluid cooler hose E

11. Fluid cooler hose F

12. Bypass valve

13. Flu ...

Off-road recovery

If the right side or left side wheels leave the road surface, maintain control

of the vehicle by following the procedure below. Please note that this procedure

is only a general guide. The vehicle must be driven as appropriate based on the

conditions of the vehicle, road and traffic.

1. Remai ...

Vehicle recovery (freeing a stuck vehicle)

WARNING

• Stand clear of a stuck vehicle.

• Do not spin your tires at high speed.

This could cause them to explode and result in serious injury. Parts of your

vehicle could also overheat and be damaged.

Pulling a stuck vehicle

Do not use the tie down hook for towing or vehicle recovery. ...