Nissan Juke Service and Repair Manual : Charging system preliminary inspection

Inspection Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair battery terminals connection.

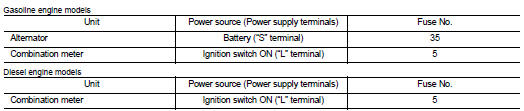

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal? YES >> GO TO 3.

NO >> Be sure to eliminate the cause of malfunction before installing new fuse.

3.CHECK “E” TERMINAL CONNECTION (ALTERNATOR GROUND)

Check if “E” terminal (alternator ground) is clean and tight.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair “E” terminal (alternator ground) connection.

4.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to the following.

• HR16DE engine models: EM-154, "Checking" • MR16DDT engine models: EM-20, "Checking" • K9K engine models: EM-276, "Checking Drive Belts"

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair as needed.

Diagnosis and repair workflow

Diagnosis and repair workflow

Gasoline engine models

GASOLINE ENGINE MODELS : Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-17, "Inspection Procedure ...

Power generation voltage variable control system operation

inspection

Power generation voltage variable control system operation

inspection

Inspection Procedure

CAUTION:

When performing this inspection, always use a charged battery that has completed

the battery inspection.

(When the charging rate of the battery is low, the respons ...

Other materials:

Light & rain sensor

Exploded View

1. Light & rain sensor bracket

2. Mirror base

3. Light & rain sensor

4. Inside mirror assembly

: Pawl

: Do not reuse

Removal and Installation

CAUTION:

When the light & rain sensor is removed from windshield, the light & rain sensor

cannot be reused.

REMO ...

P0335 CKP sensor (POS)

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perfo ...

Door lock and unlock switch

Driver side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YE ...