Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Gasoline engine models

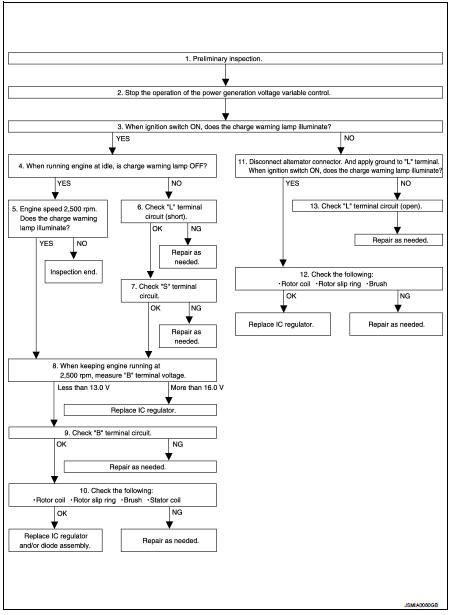

GASOLINE ENGINE MODELS : Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-17, "Inspection Procedure".

Models with battery current sensor>>GO TO 2.

Models without battery current sensor>>GO TO 3.

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures.

• After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-III, set the DUTY value of “ALTERNATOR DUTY” to 0 % by selecting “ALTERNATOR DUTY” of “Active Test”. Continue “Active Test” until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the alternator.) • Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic results history of the engine using CONSULT-III.] >> GO TO 3.

3.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 4.

NO >> GO TO 11.

4.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 5.

NO >> GO TO 6.

5.INSPECTION WITH CHARGE WARNING LAMP

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate? YES >> GO TO 8.

NO >> INSPECTION END

6.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-23, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair as needed.

7.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-24, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair as needed.

8.MEASURE “B” TERMINAL VOLTAGE

Start engine. When keeping engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show? Less than 13.0 V>>GO TO 9.

More than 16.0 V>>Replace IC voltage regulator.

9.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-20, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair as needed.

10.DISASSEMBLE AND CHECK ALTERNATOR

Check the following conditions.

• Rotor coil

• Rotor slip ring

• Brush

• Stator coil

Refer to CHG-29, "HR16DE : Inspection" (HR16DE), CHG-33, "MR16DDT : Inspection" (MR16DDT).

Are these normal? YES >> Replace IC voltage regulator and/or diode assembly.

NO >> Repair as needed.

11.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

1. Disconnect alternator connector and ground “L” harness side.

2. Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 12.

NO >> GO TO 13.

12.DISASSEMBLE AND CHECK ALTERNATOR

Check the following conditions.

• Rotor coil

• Rotor slip ring

• Brush

Refer to CHG-29, "HR16DE : Inspection" (HR16DE), CHG-33, "MR16DDT : Inspection" (MR16DDT).

Are these normal? YES >> Replace IC voltage regulator.

NO >> Repair as needed.

13.CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (open). Refer to CHG-21, "Diagnosis Procedure".

>> Repair as needed.

Diesel engine models

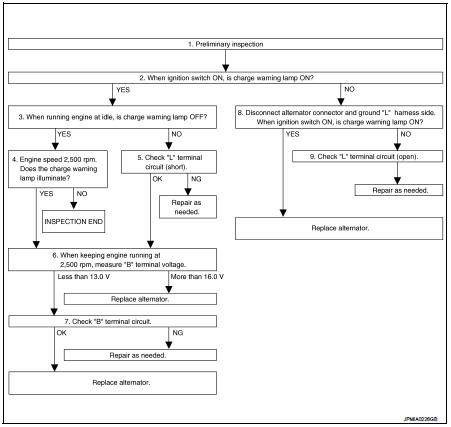

DIESEL ENGINE MODELS : Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-17, "Inspection Procedure".

>> GO TO 2.

2.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 3.

NO >> GO TO 8.

3.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 4.

NO >> GO TO 5.

4.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate? YES >> GO TO 6.

NO >> INSPECTION END

5.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-23, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair as needed.

6.MEASURE “B” TERMINAL VOLTAGE

Engine start. When keeping engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show? Less than 13.0 V>>GO TO 7.

More than 16.0 V>>Replace alternator.

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-20, "Diagnosis Procedure".

Is the inspection result normal? YES >> Replace alternator.

NO >> Repair as needed.

8.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

1. Disconnect alternator connector and ground “L” harness side.

2. Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> Replace alternator.

NO >> GO TO 9.

9.CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (open). Refer to CHG-21, "Diagnosis Procedure".

>> Repair as needed.

Basic inspection

Basic inspection

...

Charging system preliminary inspection

Charging system preliminary inspection

Inspection Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair battery ter ...

Other materials:

Security indicator lamp does not turn on or blink

Description

Security indicator lamp does not blink when ignition switch is in a position

other than ON.

NOTE:

• Before performing the diagnosis, check “Work Flow”. Refer to SEC-187, "Work

Flow".

• Check that vehicle is under the condition shown in “CONDITIONS OF VEHICLE

(OPERAT ...

Removal and Installation

REMOVAL

1. Shift the transaxle to the neutral position, and then release the parking

brake.

2. Put matching marks on propeller shaft flange yoke and final drive companion

flanges.

CAUTION:

For matching marks, use paint. Never damage propeller shaft flange yoke and

final drive companion

...

Side oil seal

Removal and Installation

REMOVAL

1. Remove front drive shafts. (MR16DDT) Refer to FAX-22, "LEFT SIDE : Removal

and Installation" (LEFT

SIDE) and FAX-24, "RIGHT SIDE : Removal and Installation" (RIGHT SIDE).

2. Remove front drive shafts. (K9K) Refer to FAX-78, "LEFT SID ...