Nissan Juke Service and Repair Manual : Back door opener switch

Component Function Check

1.CHECK FUNCTION

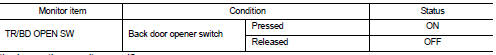

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TR/BD OPEN SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door opener switch is OK.

NO >> Refer to DLK-244, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BACK DOOR OPENER SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

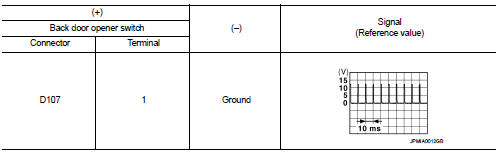

3. Check signal between back door opener switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BACK DOOR OPENER SWITCH CIRCUIT

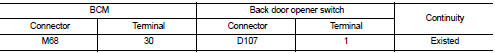

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and back door opener switch harness connector.

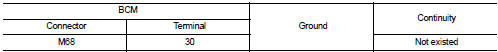

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

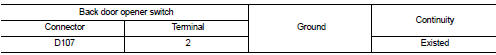

3.CHECK BACK DOOR OPENER SWITCH GROUND CIRCUIT

Check continuity between back door opener switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK BACK DOOR OPENER SWITCH

Refer to DLK-245, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace back door opener switch. Refer to BCS-93, "Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

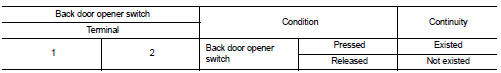

1.CHECK BACK DOOR OPENER SWITCH

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

3. Check continuity between back door opener switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace back door opener switch.

Back door opener actuator

Back door opener actuator

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “TRUNK/BACK DOOR” in “ACTIVE TEST” mode.

3. Check that the function operates normally ac ...

Back door request switch

Back door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-BD/TR” in “DATA MONITOR” mode.

3. Check that the function operates normally acco ...

Other materials:

How to use the setup button

When the SETUP button is pushed, the Setup screen will appear on the display.

You can select and/or adjust several functions, features and modes that are available

for your vehicle.

Audio setup

Select the “Audio” key to adjust the following items to the preferred setting.

These settings ...

Door cable

Exploded View

LEFT SIDE

1. A/C unit assembly

2. Intake door lever

3. Intake door link

4. Intake door cable

5. Air mix door cable

6. Upper air mix door rod

7. Upper air mix door lever

8. Lower air mix door lever

9. Lower air mix door rod

10. Air mix door link

A. To A/C control

RI ...

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Hazard warning lamp ...