Nissan Juke Service and Repair Manual : B2605 shift position

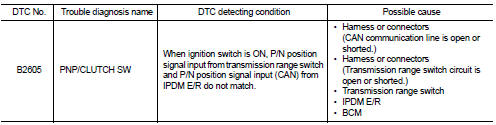

DTC Logic

DTC DETECTION LOGIC

NOTE

:

• If DTC B2605 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2605 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-84, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Shift the selector lever to the P position.

2. Turn ignition switch ON and wait 1 second or more.

3. Shift the selector lever to the N position and wait 1 second or more.

4. Shift the selector lever to any position other than P and N, and wait 1 second or more.

5. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-90, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

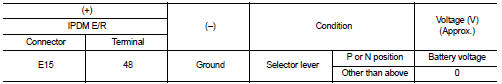

1.CHECK IPDM E/R INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

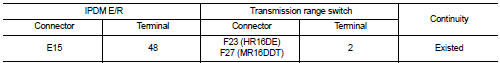

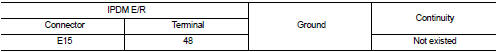

2.CHECK IPDM E/R INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect transmission range switch connector.

3. Check continuity between IPDM E/R harness connector and BCM harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

3.CHECK BCM INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK BCM INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect transmission range switch connector.

3. Disconnect BCM connector.

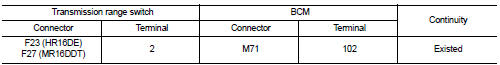

4. Check continuity between transmission range switch harness connector and BCM harness connector.

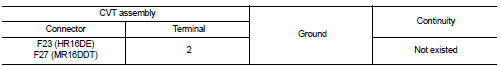

5. Check continuity between CVT assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

5.REPLACE BCM

1. Replace BCM. Refer to BCS-93, "Removal and Installation".

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT-III.

For initialization and registration procedures, refer to CONSULT-III Operation Manual NATS-IVIS/NVIS.

3. Perform DTC CONFIRMATION PROCEDURE for DTC B2605. Refer to SEC-90, "DTC Logic".

Is DTC B2605 detected again? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> INSPECTION END

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

B2604 shift position

B2604 shift position

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2604 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2604 is disp ...

B2608 starter relay

B2608 starter relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2608 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2608 is disp ...

Other materials:

System

Body control system

BODY CONTROL SYSTEM : System Description

OUTLINE

• BCM (Body Control Module) controls the various electrical components. It

inputs the information required to

the control from CAN communication and the signal received from each switch and

sensor.

• BCM has combination sw ...

U0141 lost communication (BCM A)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

Unit removal and installation

Engine assembly

Exploded View

1. Engine mounting assembly (RH)

2. Rear engine mounting bracket

3. Rear torque rod

4. Engine mounting bracket (LH)

5. Stud bolt

6. Engine mounting bracket (LH)

7. Engine mounting insulator (LH)

8. Mass damper

: N·m (kg-m, ft-lb)

CAUTION:

Check that ...