Nissan Juke Service and Repair Manual : ABS branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

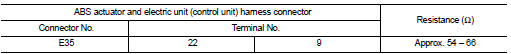

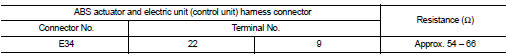

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector terminals.

- Models with ESP

- Models without ESP

Is the measurement value within the specification? YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to the following.

• Models without ESP: BRC-64, "Diagnosis Procedure" • Models with ESP: BRC-205, "Diagnosis Procedure"

Is the inspection result normal? YES (Present error)>>Replace the ABS actuator and electric unit (control unit). Refer to the following.

• Models without ESP: BRC-90, "Removal and Installation".

• Models with ESP: BRC-233, "Removal and Installation".

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

4WD branch line circuit

4WD branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend ...

IPDM-E branch line circuit

IPDM-E branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the IPDM E/R for damage, ...

Other materials:

P0705 transmission range switch A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

> ...

P17B7 high clutch solenoid

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. S ...

Keyfob battery

Component Function Check

1.CHECK FUNCTION

Check door lock and unlock operation with keyfob button.

Is the inspection result normal?

YES >> Keyfob is OK.

NO >> Refer to DLK-528, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK KEYFOB BATTERY

Check by connecting a r ...