Nissan Juke Service and Repair Manual : ABS actuator and electric unit (control unit)

Exploded View

LHD

MR16DDT (2WD), HR16DE

1. ABS actuator and electric unit (control

unit)

2. ABS actuator and electric unit (control

unit) harness connector

3. Bracket

A. To front LH caliper

B. To rear RH caliper

C. To rear LH caliper

D. To front RH caliper

E. To master cylinder secondary side

F. To master cylinder primary side

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

MR16DDT (4WD)

1. ABS actuator and electric unit (control

unit)

2. ABS actuator and electric unit (control

unit) harness connector

3. Bracket

A. To front LH caliper

B. To rear RH caliper

C. To rear LH caliper

D. To front RH caliper

E. To master cylinder secondary side

F. To master cylinder primary side

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

K9K

1. ABS actuator and electric unit (control

unit)

2. ABS actuator and electric unit (control

unit) harness connector

3. Bracket

A. To front LH caliper

B. To rear RH caliper

C. To rear LH caliper

D. To front RH caliper

E. To master cylinder secondary side

F. To master cylinder primary side

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

RHD

1. ABS actuator and electric unit (control

unit)

2. ABS actuator and electric unit (control

unit) harness connector

3. Bracket

A. To master cylinder secondary side

B. To master cylinder primary side

C. To front LH caliper

D. To rear RH caliper

E. To rear LH caliper

F. To front RH caliper

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Install

REMOVAL

1. Disconnect battery cable from negative terminal.

2. Drain brake fluid.

• LHD: Refer to BR-12, "Draining".

• RHD: Refer to BR-80, "Draining".

3. Remove air cleaner case and air duct. (RHD) Refer to EM-161, "Removal and Installation".

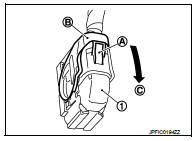

4. Disconnect ABS actuator and electric unit (control unit) harness connector (1), follow the procedure described below.

a. Push the pawl (A).

b. Move the lever (B) in the direction (C) until locked.

c. Disconnect ABS actuator and electric unit (control unit) harness connector.

5. Loosen flare nut of brake tube using a flare nut wrench, and then remove brake tube from ABS actuator and electric unit (control unit).

• LHD Refer to BR-24, "FRONT : Exploded View".

• RHD Refer to BR-91, "FRONT : Exploded View"

6. Remove ABS actuator and electric unit (control unit) and bracket.

CAUTION

:

• Never remove and never install ABS actuator and electric unit (control unit)

by holding harness

connector.

• Be careful not to drop ABS actuator and electric unit (control unit) and apply excessive impact to it.

7. Remove bracket and bushing from ABS actuator and electric unit (control unit).

INSTALLATION

Note the following, and install in the reverse order of removal.

• When replacing with a new ABS actuator and electric unit (control unit), never remove the protector of the brake tube mounting hole until right before the brake tube is installed.

• When installing brake tube, tighten to the specified torque using a flare nut torque wrench so that flare nut and brake tube are not damaged.

- LHD: Refer to BR-24, "FRONT : Exploded View".

- RHD: Refer to BR-91, "FRONT : Exploded View".

• Never remove and install ABS actuator and electric unit (control unit) by holding actuator harness.

• Bleed air from brake piping after installation.

- LHD: Refer to BR-13, "Bleeding Brake System".

- RHD: Refer to BR-81, "Bleeding Brake System".

• Never apply excessive impact to actuator, such as by dropping it.

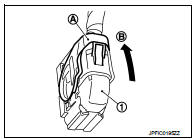

• After installing the ABS actuator and electric unit (control unit) harness connector (1), move the lever (A) in the direction (B) to secure the locking.

Sensor rotor

Sensor rotor

Front sensor rotor : Removal and Installatio

REMOVAL

Replace wheel hub as an assembly when replacing because sensor rotor cannot

be disassembled.

• MR16DDT: Refer to FAX-11, "Removal and I ...

Yaw rate/side/decel G sensor

Yaw rate/side/decel G sensor

Exploded View

1. Yaw rate/side/decel G sensor

2. Yaw rate/side/decel G sensor harness

connector

3. Bracket

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

CAUTION:

Ne ...

Other materials:

B1147 curtain air bag module RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

P0237, P0238 TC boost sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...

General maintenance

General Maintenance

General maintenance includes those items which should be checked during the

normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating

properly. The owners can perform

checks and inspections themselves or they can have their NISS ...