Nissan Juke Service and Repair Manual : A/C on signal

Component Function Check

1.CHECK A/C ON SIGNAL

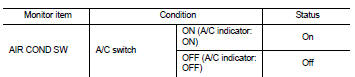

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Operate blower motor.

3. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

4. Select “AIR COND SW” in “DATA MONITOR” mode.

5. Check A/C ON signal when the A/C switch is operated.

Is the inspection result normal? YES >> INSPECTION END

NO >> Refer to HAC-166, "Diagnosis Procedure".

Diagnosis Procedure

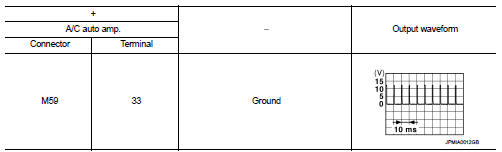

1.CHECK A/C ON SIGNAL

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch ON.

4. Check output waveform between A/C auto amp. harness connector and ground with using oscilloscope.

Is the inspection result normal? YES >> Replace A/C auto amp. Refer to HAC-188, "Removal and Installation".

NO >> GO TO 2.

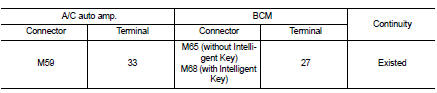

2.CHECK A/C ON SIGNAL CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between A/C auto amp. harness connector and BCM harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair harness or connector.

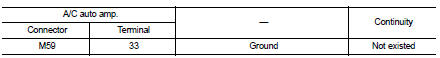

3.CHECK A/C ON SIGNAL CIRCUIT FOR SHORT

Check continuity between A/C auto amp. harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key) or BCS-161, "Removal and Installation" (without Intelligent Key).

NO >> Repair harness or connector.

Door motor

Door motor

Diagnosis Procedure

NOTE:

If all of door motor DTCs are detected, check this circuit.

1.CHECK DOOR MOTOR POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between intake door motor harn ...

Blower fan on signal

Blower fan on signal

Component Function Check

1.CHECK BLOWER FAN ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “FAN ON SIG” in “DATA MONITOR” ...

Other materials:

Manual air conditioner (if so equipped)

1. Air intake lever (Outside air circulation

/Air recirculation

)

2. Air flow control dial

3. Fan speed control dial

4. A/C (Air Conditioner) button

5. Temperature control dial

6. Rear window defroster button (See

“Rear window and outside mirror defroster switch” .)

To turn off the he ...

Passenger compartment

CAUTION

Never use a fuse of a higher or lower amperage rating than that specified

on the fuse box cover. This could damage the electrical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse.

1. Be sure the ignition switch and the headlight switch are t ...

P1544 EGT sensor 2

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P1544 is displayed with DTC P0115, first perform trouble diagnosis for

DTC P0115. Refer to EC-907,

"DTC Logic".

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground ...