Nissan Juke Service and Repair Manual : Water hose

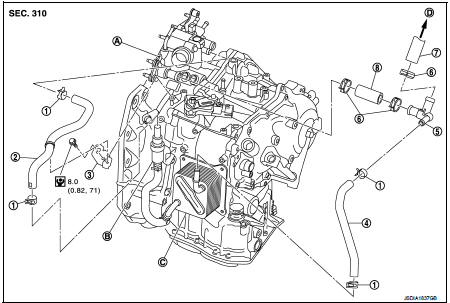

Exploded View

1. Hose clamp

2. Water hose A

3. Water hose B

4. Water hose B

5. Water bypass pipe

6. Hose clamp

7. Heater hose

8. Water hose C

A. Water outlet

B. Heater thermostat

C. Oil warmer

D. Heater core

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur

from high pressure

coolant escaping from the radiator.

CAUTION:

Perform these steps after the coolant temperature has cooled sufficiently.

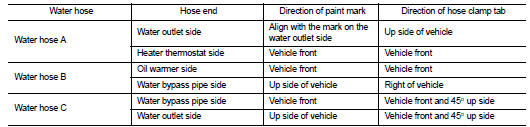

1. Remove the hose clamp and pull out the water hose A.

2. Remove the hose clamp and pull out the water hose B.

3. Remove the hose clamp and pull out the water hose C.

4. Pull out the heater hose and remove the water bypass pipe. Refer to CO-52, "Exploded View".

5. Remove the bracket.

INSTALLATION

Note the following, and install in the reverse order of removal.

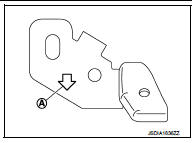

• To install bracket to the CVT assembly, face the from arrow (A) of the bracket ahead of the vehicle.

• When installing water hose (1) to tube (2), refer to insertion length “A” below.

Insertion length “A” : 27 mm (1.06 in)

• When hose clamp (1) is installed on CVT water hose (2), refer to dimension “A” below.

Dimension“A” : 5 – 7 mm (0.20 – 0.28 in)

• The hose clamp should not come on bulge (B).

Inspection

INSPECTION AFTER INSTALLATION

Start the engine, and check the joints for coolant leakage.

Differential side oil seal

Differential side oil seal

Exploded View

1. Transaxle assembly

2. Differential side oil seal (left side)

3. Differential side oil seal (right side)

: Vehicle front

: Always replace after every

disassembly.

: Genuine N ...

Fluid cooler system

Fluid cooler system

Exploded View

1. Bracket

2. Bracket

3. Bracket

4. CVT fluid cooler

5. Clamp

6. CVT fluid cooler hose C

7. CVT fluid cooler hose B

8. CVT fluid cooler tube assembly

9. CVT fluid cooler ...

Other materials:

Wiring diagram

SRS AIR BAG SYSTEM

Wiring Diagram

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to GI-12, "Connector Information/Explanation

of Option Abbreviation".

...

Rear door lock

Exploded View

1. Outside handle assembly

2. Rear door sealing screen

3. Door lock assembly

4. TORX bolt

5. Inside handle

: Clip

: Pawl

: Vehicle front

: Do not reuse

: N·m (kg-m, in-lb)

: Body grease

Door lock

DOOR LOCK : Removal and Installation

REMOVAL

1. Remove rear door glass ...

Getting started

The following procedures will help you get started using the Bluetooth® Hands-Free

Phone System with NISSAN Voice Recognition. For additional command options, refer

to “List of voice commands” .

Choosing a language

You can interact with the Bluetooth® Hands- Free Phone System using English,

...