Nissan Juke Service and Repair Manual : Fluid cooler system

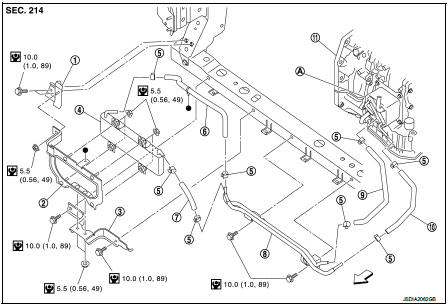

Exploded View

1. Bracket

2. Bracket

3. Bracket

4. CVT fluid cooler

5. Clamp

6. CVT fluid cooler hose C

7. CVT fluid cooler hose B

8. CVT fluid cooler tube assembly

9. CVT fluid cooler hose D

10. CVT fluid cooler hose A

11. Transaxle assembly

A. CVT oil warmer

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Remove front bumper assembly. Refer to EXT-13, "Removal and Installation".

2. Remove inlet air duct (lower). Refer to EM-161, "Removal and Installation".

3. Remove air guide (LH and RH). Refer to DLK-147, "HR16DE : Exploded View".

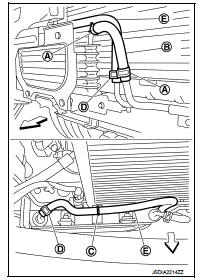

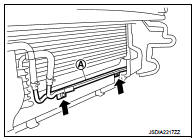

4. Remove hose clamps (A) and fluid cooler hose B (B).

: Vehicle front

: Vehicle front

5. Disconnect clip (C) from bracket.

6. Remove hose clamps (D) and fluid cooler hose C (E).

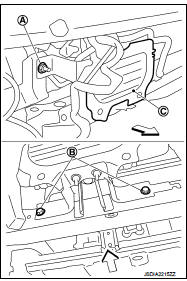

7. Remove nut (A) and bolts (B).

: Vehicle front

: Vehicle front

8. Remove CVT fluid cooler (with brackets) (C) from the vehicle.

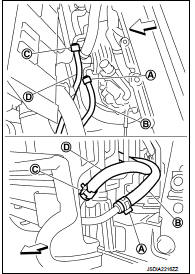

9. Remove clamps (A) and fluid cooler hose A (B).

: Vehicle front

: Vehicle front

NOTE

:

Cap or plug openings to prevent fluid from spilling.

10. Remove clamps (C) and fluid cooler hose A (D).

NOTE

:

Cap or plug openings to prevent fluid from spilling.

11. Remove CVT fluid cooler tube assembly (A) from the vehicle.

: Bolt

: Bolt

INSTALLATION

Note the following, and Install in the reverse order of removal.

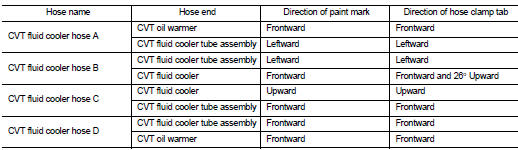

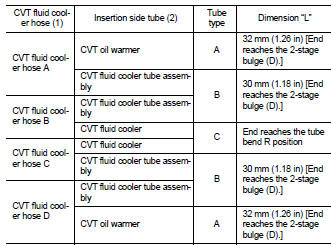

• Refer to the following when installing CVT fluid cooler hoses.

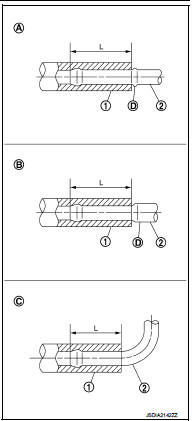

- Insert CVT fluid cooler hose according to dimension “L” described below.

- Set hose clamps (1) at the both ends of CVT fluid cooler hoses (2) with dimension “A” from the hose edge.

Tube type A, B Dimension “A” : 5 – 9 mm (0.20 – 0.35 in) Tube type C Dimension “A” : 5 mm (0.20 in)

- Hose clamp should not interfere with the bulge of fluid cooler tube.

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-480, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-379, "Adjustment".

Water hose

Water hose

Exploded View

1. Hose clamp

2. Water hose A

3. Water hose B

4. Water hose B

5. Water bypass pipe

6. Hose clamp

7. Heater hose

8. Water hose C

A. Water outlet

B. Heater thermostat

C ...

Plug

Plug

Description

Replace the O-ring if oil leakage or exudes from the plug.

Exploded View

1. Plug

2. O-ring

3. O-ring

4. Plug

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: ...

Other materials:

Camshaft

*: Total indicator readin

VALVE LIFTER

VALVE CLEARANCE

*: Approximately 80°C (176°F)

AVAILABLE VALVE LIFTER

...

C1101, C1102, C1103, C1104 WHEEL SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

Main line betweeN DLC and MDU circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the following harness connectors.

- ECM

- Multi display unit

4. Check the continuity between the data link connector and the ...