Nissan Juke Service and Repair Manual : Upper link

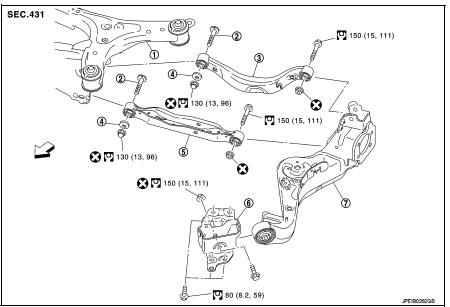

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. WT-7, "Removal and Installation".

2. Remove wheel sensor and sensor harness. Refer to BRC-86, "REAR WHEEL SENSOR : Removal and Installation" (Without ESP), BRC-227, "REAR WHEEL SENSOR : Removal and Installation" (With ESP).

3. Set jack under suspension arm.

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack.

4. Remove eccentric disc, adjusting bolt, mounting bolt, and nut, then remove upper link.

5. Perform inspection after removal. Refer to RSU-33, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member and axle installation position (rubber bushing), under unladen conditions with tires on level ground.

• Never reuse upper link mounting nut.

• Perform inspection after installation. Refer to RSU-33, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check upper link and bushing for any deformation, cracks, or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer toBRC-85, "REAR WHEEL SENSOR : Exploded View" (Without ESP), BRC-225, "REAR WHEEL SENSOR : Exploded View" (With ESP).

2. Check wheel alignment. Refer to RSU-20, "Inspection".

3. Adjust neutral position of steering angle sensor. Refer to BRC-149, "Work Procedure" (With ESP).

Lower link

Lower link

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Rear stabilizer

Rear stabilizer

Exploded View

1. Stabilizer bar

2. Bushing

3. Stabilizer clamp

4. Stabilizer link

5. Lower link

6. Rear suspension member

: Vehicle front

: Always replace after every

disassembly.

: N ...

Other materials:

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any of

the cu ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

P0226 APP sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...