Nissan Juke Service and Repair Manual : Precaution for Brake System

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust

collector. Never blow by compressed

air.

• Brake fluid use refer to MA-13, "Fluids and Lubricants".

• Never reuse drained brake fluid.

• Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface.

• Always confirm the specified tightening torque when installing the brake pipes.

• After pressing the brake pedal more deeply or harder than normal driving, such as air bleeding, check each item of brake pedal. Adjust brake pedal if it is outside the standard value.

• Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause improper operation.

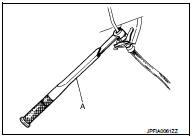

• Always loosen the brake tube flare nut with a flare nut wrench.

• Tighten the brake tube flare nut to the specified torque with a flare nut torque wrench (A).

• Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) harness connector or the battery negative terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the parts.

Precaution for Procedure without Cowl Top Cover

Precaution for Procedure without Cowl Top Cover

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

...

Precaution for Brake Control system

Precaution for Brake Control system

• Always perform a pre-driving check to drive the vehicle.

• Always check speed and safety while driving the vehicle.

• To operate CONSULT-III while driving, more than one person is required to be

...

Other materials:

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosis Description" (without Intelligent Key).

Does it operate normally?

YES >> INSPECTION ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...