Nissan Juke Service and Repair Manual : Lower link

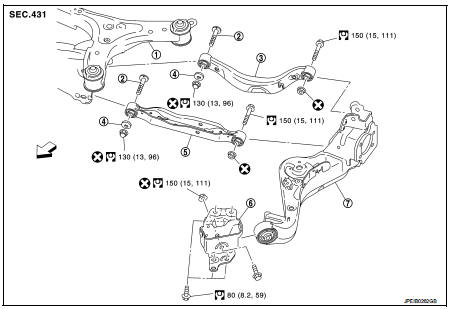

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Set jack under suspension arm.

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack

.

3. Remove stabilizer link. Refer to RSU-34, "Removal and Installation".

4. Remove eccentric disc, adjusting bolt, mounting bolt, and nut, then remove lower link.

5. Perform inspection after removal. Refer to RSU-31, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member and axle installation position (rubber bushing), under unladen conditions with tires on level ground.

• Never reuse lower link mounting nut.

• Perform inspection after installation. Refer to RSU-31, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check lower link and bushing for any deformation, cracks, or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel alignment. Refer to RSU-20, "Inspection".

2. Adjust neutral position of steering angle sensor. Refer to BRC-149, "Work Procedure" (With ESP).

Suspension arm

Suspension arm

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Upper link

Upper link

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Other materials:

P2765 clutch B speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

> ...

On board diagnostic (OBD) system

Diagnosis Description

This system is an on board diagnostic system that records exhaust

emission-related diagnostic information

and detects a sensors/actuator-related malfunction. A malfunction is indicated

by the malfunction indicator

lamp (MIL) and stored in ECU memory as a DTC. The diagnos ...

Engine cooling system

The engine cooling system is filled at the factory with a pre-diluted mixture

of 50% Genuine NISSAN Long Life Antifreeze/Coolant (blue) and 50% water to provide

year-round anti-freeze and coolant protection. The anti-freeze solution contains

rust and corrosion inhibitors. Additional engine coo ...